Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-11

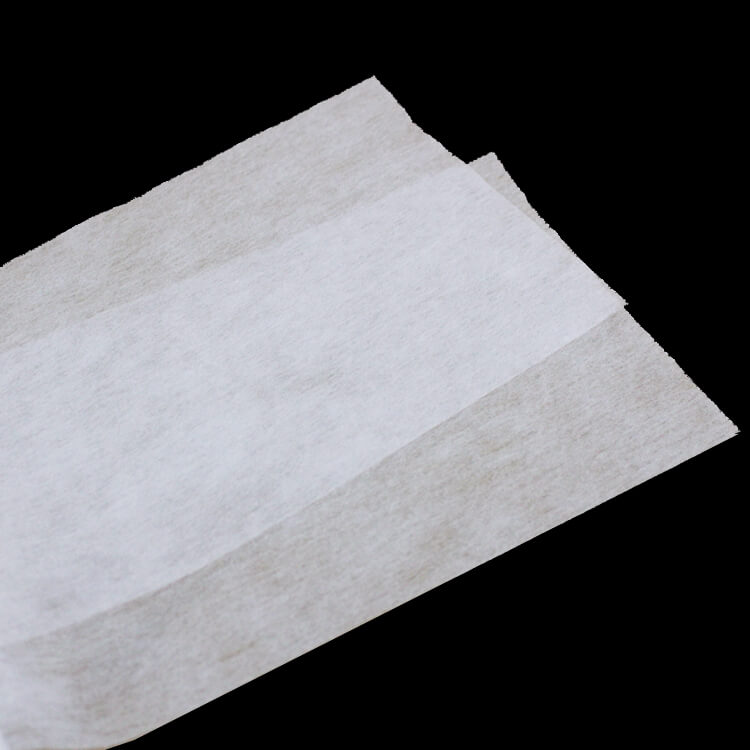

Diapers are an essential product that plays a significant role in ensuring the comfort and hygiene of infants and toddlers. The manufacturing process of diapers involves the utilization of various materials, including laminated non-woven fabric. Laminated non-woven fabric offers versatility and durability, making it a popular choice in diaper manufacturing. This article explores the versatile applications of laminated non-woven fabric and its benefits in the production of diapers.

The ability to absorb and distribute liquid is a crucial factor in the design and functionality of diapers. Laminated non-woven fabric is often used as the top sheet, which comes into contact with the baby's skin. It is designed to quickly absorb and disperse urine, keeping the surface dry and preventing rashes or irritation. The laminated layer enhances the fabric's liquid resistance, preventing leakage and providing added protection. The combination of these features ensures the baby remains comfortable and dry for extended periods.

Adequate air circulation and breathability are essential for maintaining the health and well-being of a baby's sensitive skin. Laminated non-woven fabric used in diaper manufacturing allows for air permeability while still maintaining its liquid-absorbing properties. The micro-pores in the fabric enable the passage of air, preventing the build-up of heat and moisture. This feature helps to reduce the occurrence of diaper rash and keeps the baby's skin moisturized and fresh.

Babies have delicate and sensitive skin, requiring materials that are soft and gentle to avoid discomfort. Laminated non-woven fabric provides a soft and smooth surface that is gentle on the baby's skin. The fabric is also flexible, allowing for a comfortable fit and ease of movement. The flexibility of the laminated non-woven fabric ensures the diaper molds to the baby's body shape, preventing leakage and providing maximum comfort.

In conclusion, laminated non-woven fabric offers a range of versatile applications in the manufacturing of diapers. Its liquid absorption and distribution properties, breathability, softness, and flexibility make it an ideal material for creating high-quality diapers that prioritize the well-being and comfort of infants. With the utilization of laminated non-woven fabric, manufacturers can provide parents with reliable and efficient diapers that meet the needs of their little ones.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China