Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Baby diaper, Adult diaper, Sanitary napkin

Minimum order quanity: 1000.00 kgs

Packing details: Transparent wrapping film with paper board

Air through non woven fabric is a kind of hot air bonding (hot rolling, hot air) non woven fabric. Hot air non woven is to use the hot air on the drying equipment to penetrate the fiber web after the fibers are combed, so that they are heated and dried. The resulting non-woven fabric can be bonded.

Weight: 18 – 50gsm

Width: 65mm-3600mm

Inner core diameter: 76mm

Outer diameter:580-780mm

Loading quantity:9-10tons/40HQ

|

Items |

Unit |

Requirement |

Result |

||

|

Min |

Max |

||||

|

Color |

/ |

white |

white |

||

|

Core inside diameter |

mm |

76±1 |

76 |

||

|

Basic weight |

gsm |

18±2 |

17.2 |

18.9 |

|

|

Width |

mm |

180±2 |

179 |

181 |

|

|

3D- Dimensional Thickness |

mm |

-0.2+0.3 |

0.43 |

0.49 |

|

|

Tensile strength |

MD |

N/5cm |

≥11 |

12.9 |

15.5 |

|

CD |

≥1.7 |

2.4 |

3.5 |

||

|

Breaking elongation |

MD |

% |

≥18 |

54 |

60 |

|

CD |

≥20 |

95 |

115 |

||

|

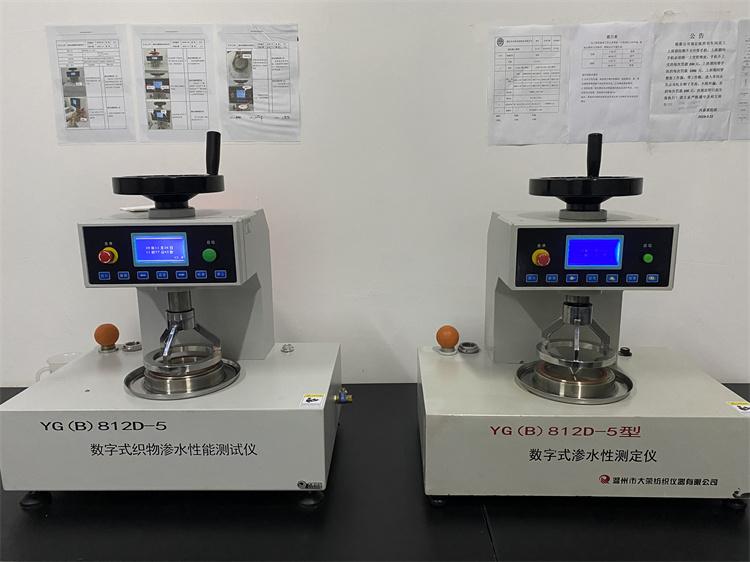

Fluid Penetrating Rate |

1st |

S |

≤2 |

1.03 |

1.25 |

|

2nd |

≤3 |

2.04 |

2.37 |

||

|

3rd |

≤4 |

2.6 |

3.01 |

||

|

Others |

Wrinkles/ corrugation |

None |

|||

|

Roll edge appearance |

Neat, Clean, No Obvious Defects |

||||

|

Contamination |

No Obvious Contamination; Free From Foreign Matter |

||||

|

Holes/Thin spots/Formation |

No Obvious Holes / Thin Spots / With Good Formation |

||||

Hot air non woven fabric is made ofcompound fibers which causes no stimulation or allergy to human body. They haveachieved the national standard of hygiene pads production. They te...

1. LegcuffSMMS non woven fabrics (Spunbond + Meltblown + Meltblown + Spunbond Nonwovens),basic weight range: 10-100 gsm; width: 90mm-3200mm; it belongs to composite nonwoven fabric...

Air through non woven fabric is a kind ofhot air bonding (hot rolling, hot air) non woven fabric. Hot air non woven isto use the hot air on the drying equipment to penetrate the fi...

We export untreated fluff pulp toBangladesh customer. Untreated fluff pulp is used for babydiaper, sanitary napkin and adult diaper. Untreated fluff pulp is shortage all whol...

There are different kinds of diaper non woven. Topsheet non woven can be spunbond hydrophilic non woven, hot air hydrophilic non woven, thermal bond non woven. ADL non woven is use...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China