Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-10

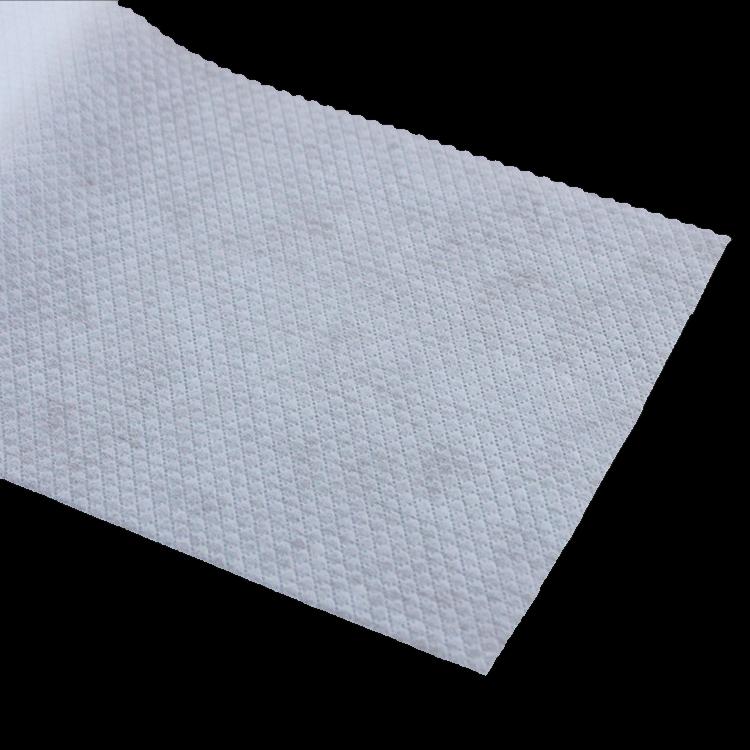

Embossed hydrophilic air through non-woven fabric is a kind of dry-process thermally bonded nonwoven fabric, which is carded into a web by short fibers. After the fibers are carded into a web, the hot air on the drying equipment is used to penetrate the fiber web and heated by hot air. , Reinforced non-woven fabrics. Because the air-through nonwoven fabric has a three-dimensional structure and good resilience, the pores of its fibers can temporarily store more than 10 times its own weight of liquid, and there are many through holes, low density, and fluffy structure, so the penetration time is short and effective. It is conducive to the rapid transmission of urine, and by adjusting the aspect ratio of the fiber laying net, the nonwoven fabric can have flow-conducting properties.

The production process of Embossed hydrophilic air through non woven fabric requires the use of sheath-core bicomponent composite fibers. Usually the skin layer is polyethylene (PE), and the core layer is polypropylene (PP) or polyester (PET). For example, PP and PE are compounded. Due to the different melting points of the two components, the melting point of the skin layer is low and the melting point of the core layer is high. , while the core polymer does not melt. The melted fibers on the surface layer are overlapped and bonded together; the polymer in the core layer does not change, and plays a supporting role in the whole process, so that the structure of the fiber web is not damaged.

The entire fiber web is output from the hot air oven after heating and bonding, and is cooled to form a hot air nonwoven fabric with a certain strength and elongation. The crossing points of the fibers of the low-melting point component form melt-bonding, and the non-crossing points are in a natural state. After cooling, the fibers at the non-intersection points remain in their original state, and the fibers at the intersection points are bonded together by "welding" of the polymer. This is a form of point bonding, so the air-through nonwoven has very good bulk, softness and high elasticity.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China