Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-09-11

Exploring the Versatile Applications of Spunlace Nonwoven in Diaper Manufacturing

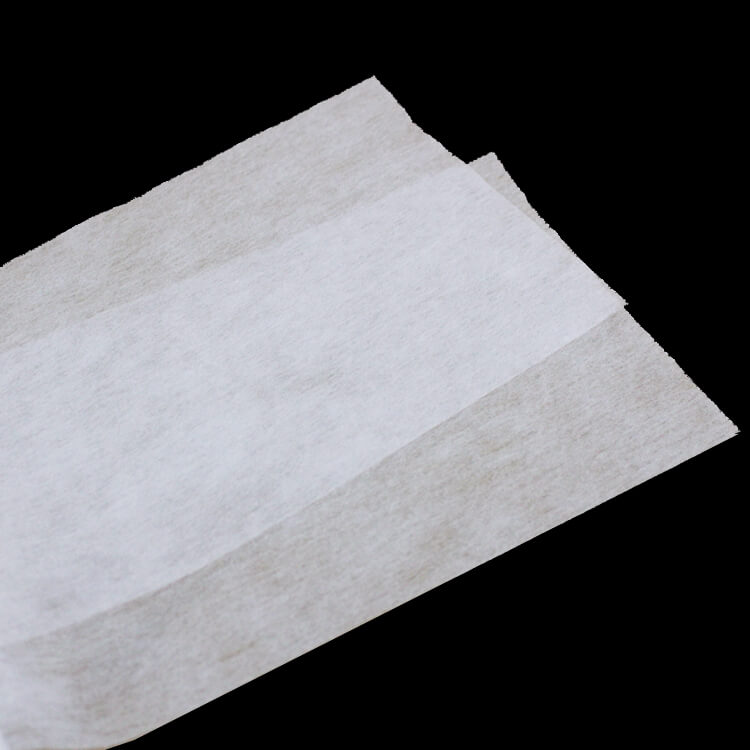

The diaper manufacturing industry has witnessed significant advancements in recent years, thanks to the introduction of innovative materials and technologies. One such material that has gained popularity is spunlace nonwoven. Spunlace nonwoven is a versatile fabric made through a high-pressure water jet process. It offers numerous benefits in diaper production, including enhanced softness, superior absorbency, and improved comfort for babies. This article aims to explore the various applications of spunlace nonwoven in diaper manufacturing.

Softness and comfort are crucial factors in diaper design, as they directly affect the overall satisfaction of both babies and parents. Spunlace nonwoven is renowned for its exceptional softness, making it an ideal choice for the inner layer of diapers. The fabric's fine fibers offer a gentle touch on the baby's skin, minimizing the risk of irritation or rashes. Additionally, spunlace nonwoven has a breathable structure, allowing air circulation and reducing the likelihood of heat build-up, thereby maximizing comfort for the baby during extended wear.

Furthermore, the high-quality texture of spunlace nonwoven helps prevent the formation of lumps or clumps, ensuring an even and smooth surface for the diaper. This feature contributes to a more comfortable experience for the baby, as it eliminates potential pressure points or uneven distribution of wetness.

Effective absorbency and moisture control are critical aspects of diaper functionality. Spunlace nonwoven excels in these areas, making it a preferred choice for the absorption core of diapers. The fabric's unique production process creates a three-dimensional structure, allowing for enhanced liquid absorption and distribution.

The high water retention capacity of spunlace nonwoven ensures that the diaper efficiently locks in moisture, keeping the baby's skin dry and preventing skin irritation. The fabric's ability to disperse liquid evenly across the diaper's surface aids in preventing leakage, providing an added layer of protection for the baby.

In addition to its performance benefits, spunlace nonwoven also contributes to improved manufacturing efficiency in the diaper industry. The fabric's consistent and uniform properties allow for easier processing and integration into the diaper production line.

The high strength and durability of spunlace nonwoven facilitate efficient handling during manufacturing, reducing the risk of tearing or damage. Moreover, the fabric's compatibility with various diaper manufacturing techniques, such as ultrasonic bonding or adhesive application, enhances production versatility and flexibility.

Spunlace nonwoven has revolutionized the diaper manufacturing industry, offering a wide range of benefits in terms of softness, comfort, absorbency, moisture control, and manufacturing efficiency. The versatility of this fabric has made it an essential component in modern diaper design and production. As technology continues to advance, we can expect further innovations and improvements in spunlace nonwoven, enabling even more remarkable applications in the future.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China