Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-07

Unveiling the Versatile Use of SMMS Material in Diaper Production

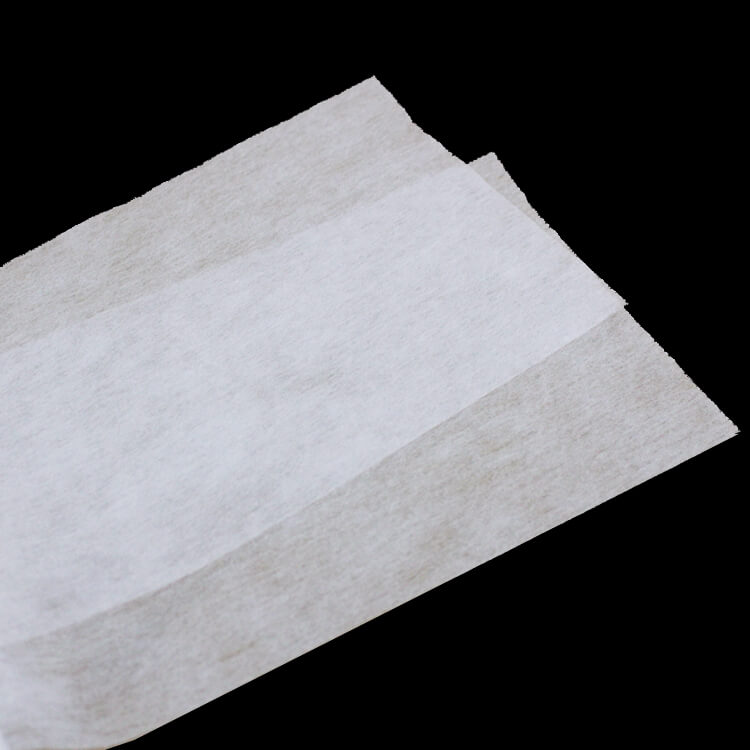

The ever-evolving diaper industry constantly seeks innovative materials to enhance the performance and comfort of diapers. In recent years, a material called SMMS (Spunbond-Meltblown-Meltblown-Spunbond) has gained popularity due to its exceptional versatility and superior properties. In this article, we will explore the various applications of SMMS material in diaper production and its impact on the industry.

SMMS material offers several key advantages that make it an ideal choice for diaper production. Firstly, its unique structure provides excellent liquid absorption and retention capabilities, ensuring maximum dryness for the baby's skin. Secondly, SMMS material is breathable and allows air circulation, reducing the risk of diaper rash and maintaining comfort for the baby. Additionally, SMMS material has high tensile strength and tear resistance, resulting in a durable and long-lasting diaper.

SMMS material finds wide-ranging applications in various components of a diaper. The outer layer, typically made of spunbond fabric, provides a soft touch and adds to the overall aesthetics of the diaper. The inner layers, composed of meltblown fabric, act as the absorbing and distributing medium for liquids, effectively preventing leakage. The use of multiple meltblown layers enhances the absorption capacity of the diaper, making it suitable for overnight use. Moreover, the spunbond fabric in the core helps maintain the structural integrity of the diaper, ensuring a snug fit.

In addition to the primary components, SMMS material can be utilized in the manufacturing of diaper fasteners, such as adhesive tapes and velcro straps. The strong bonding properties of SMMS provide a reliable fastening mechanism, facilitating easy application and adjustment of the diaper. This ensures a secure fit, preventing any discomfort or leakage.

Furthermore, SMMS material is compatible with various printing techniques, allowing for vibrant and attractive designs on the outer layer of the diaper. This feature offers a wide range of customization options for diaper manufacturers, enabling them to cater to the preferences of their target consumers.

The versatile use of SMMS material in diaper production has revolutionized the industry by offering superior performance, enhanced comfort, and aesthetic appeal. Its multi-layered structure, liquid absorption capabilities, breathability, and strength make it an ideal choice for providing the best possible experience for both babies and parents. As the demand for high-quality diapers continues to grow, the incorporation of SMMS material paves the way for further advancements in the industry, ensuring the well-being and satisfaction of diaper users worldwide.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China