Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-12

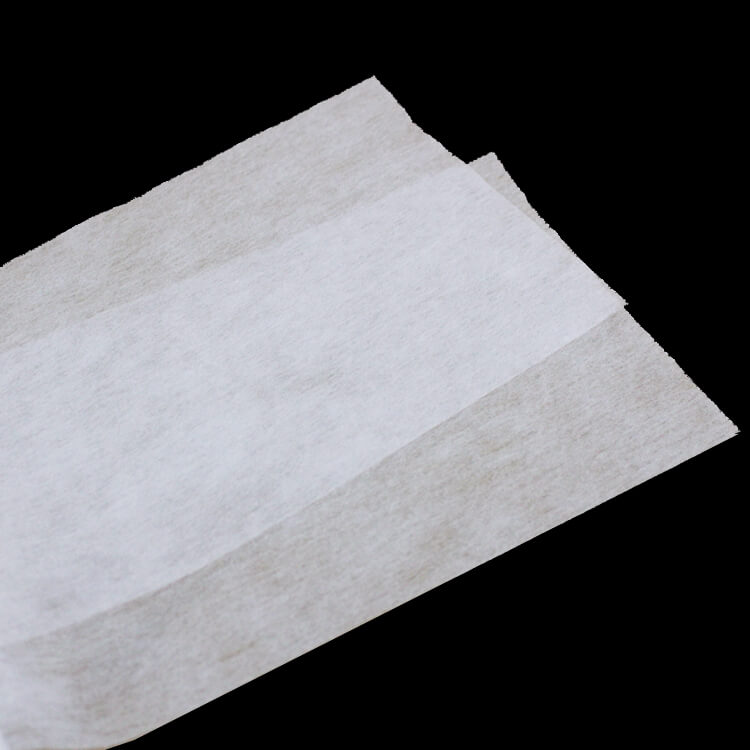

PP nonwoven fabric, also known as polypropylene nonwoven fabric, has become an essential material in the manufacturing of diapers due to its versatile applications. This fabric is widely used for its excellent absorbency, softness, and breathability, making it an ideal choice for diaper production. In this article, we will explore the various applications of PP nonwoven fabric in diaper manufacturing.

The top sheet of a diaper is the layer that comes in contact with the baby's skin. PP nonwoven fabric is commonly used as the top sheet material due to its soft texture and breathability. It provides a comfortable and gentle surface for the baby, preventing rashes and irritations. The hydrophilic nature of PP nonwoven fabric ensures quick absorption and dispersion of moisture, keeping the baby's skin dry and preventing diaper rash. Moreover, its high tensile strength ensures that the fabric does not tear or break during use.

The acquisition distribution layer is responsible for distributing and absorbing liquid within the diaper. PP nonwoven fabric, with its excellent absorption capacity, is ideal for this purpose. The fabric can effectively distribute the liquid throughout the diaper, preventing leakage and providing long-lasting dryness. Additionally, the porous structure of PP nonwoven fabric allows for rapid absorption, ensuring that the baby remains comfortable even during heavy wettings. The ADL made of PP nonwoven fabric plays a crucial role in enhancing the overall performance of the diaper.

The back sheet of a diaper is the outermost layer that prevents leakage and ensures the diaper remains intact. PP nonwoven fabric is commonly used as the back sheet material due to its waterproof and breathable properties. The fabric acts as a barrier against liquids, preventing them from leaking out of the diaper while allowing air to circulate, reducing the risk of diaper rash. The high tensile strength of PP nonwoven fabric ensures the back sheet remains intact and does not tear or break, even during active movement.

In conclusion, PP nonwoven fabric plays a vital role in diaper manufacturing due to its versatile applications. Whether it's used as the top sheet, acquisition distribution layer, or back sheet, this fabric provides exceptional absorbency, softness, and breathability. Its ability to keep the baby's skin dry and comfortable, while preventing leakage and irritation, makes it an essential component of high-quality diapers. With ongoing advancements in technology, PP nonwoven fabric continues to evolve, providing even better performance and comfort for babies.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China