Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-08

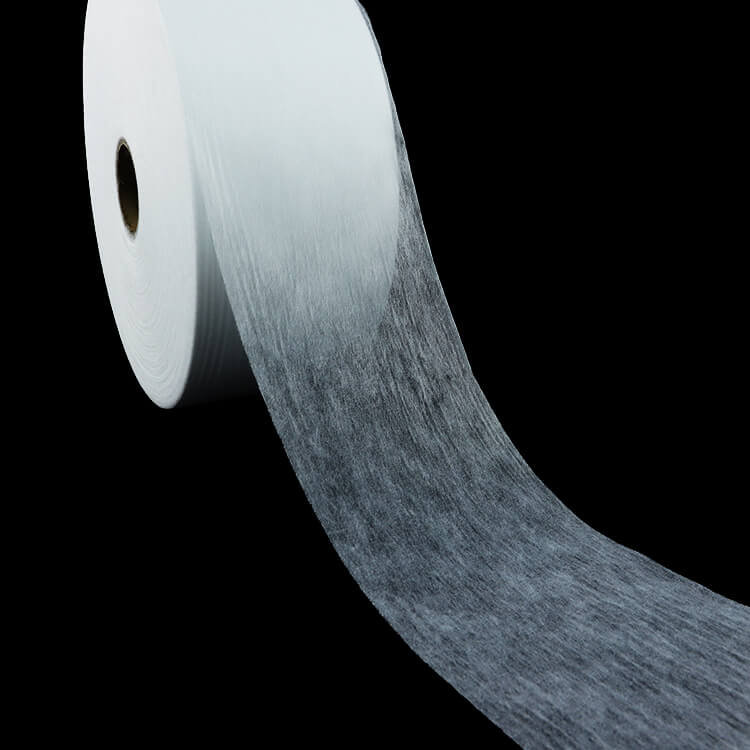

Unveiling the Versatility of Non-Woven Needle Punched Polypropylene Fabric in Diaper Manufacturing

The diaper manufacturing industry has witnessed significant advancements in recent years, with manufacturers constantly striving to enhance the performance and comfort of their products. One crucial element in the production process that plays a pivotal role in achieving these goals is the choice of materials. In this article, we will delve into the versatility and benefits of using non-woven needle punched polypropylene fabric in diaper manufacturing.

One of the fundamental characteristics of non-woven needle punched polypropylene fabric is its exceptional absorbency. The unique needle punching technique creates a porous structure with interconnected fibers, allowing for efficient moisture absorption and retention. This fabric's ability to quickly wick away moisture from the baby's skin helps maintain dryness and prevent diaper rash, ensuring the comfort and well-being of the infant.

Furthermore, the breathability of non-woven needle punched polypropylene fabric enables the timely evaporation of trapped moisture, reducing the risk of bacterial growth and infections. This promotes a healthy environment, minimizing the chances of skin irritations and discomfort for the baby. Additionally, the fabric's moisture control properties contribute to improved odor control, keeping the diaper smelling fresh and clean throughout use.

Comfort is of utmost importance in diaper design, as it directly affects the baby's overall satisfaction and contentment. Non-woven needle punched polypropylene fabric excels in providing a soft, gentle touch against the baby's delicate skin. The fine fibers and needle-punching process create a fabric with a smooth surface, devoid of any rough or irritating components.

Moreover, this fabric is renowned for its lightweight and flexible nature, enabling unrestricted movement for the baby. It molds to the contours of the body, ensuring a snug fit without causing any discomfort or friction. The softness of non-woven needle punched polypropylene fabric enhances the overall user experience, enabling the baby to feel at ease and more relaxed.

Manufacturers must consider the durability and longevity of diaper materials to ensure products can withstand the demands of daily use. Non-woven needle punched polypropylene fabric excels in this aspect, exhibiting excellent strength and resilience. The interlocked fibers created through the needle-punching process result in a fabric that can withstand repetitive movements, stretching, and stress.

This fabric's exceptional tear resistance ensures the diaper remains intact during use, eliminating the risk of leakage and providing parents with peace of mind. Furthermore, non-woven needle punched polypropylene fabric is highly resistant to chemical exposure and degradation, ensuring its performance and quality are maintained even after multiple washes. This durability contributes to the overall cost-effectiveness of diaper manufacturing, as it reduces the need for frequent product replacements.

In conclusion, the utilization of non-woven needle punched polypropylene fabric in diaper manufacturing offers numerous advantages. From enhanced absorbency and moisture control to exceptional softness and durability, this versatile material contributes significantly to the overall comfort, functionality, and longevity of diapers. As the industry continues to innovate and meet evolving consumer demands, it is evident that non-woven needle punched polypropylene fabric will remain a key element in the development of high-quality diapers.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China