Introduction. Enhanced Leakage Protection. Improved Absorbency. Cost-effective and Eco-friendly. Conclusion....

1. Enhanced Absorbency and Leakage Prevention. 2. Breathability and Comfort. 3. Cost-effective and Eco-friendly Solution....

Water proof spunbond non woven fabric is a crucial material used in diaper production. It is known for its durability, waterproofing properties, and ability to ...

1.Water proof spunbond non woven fabric production line The doubling of the water proof spunbond non woven fabric production line refers to the phenomenon tha...

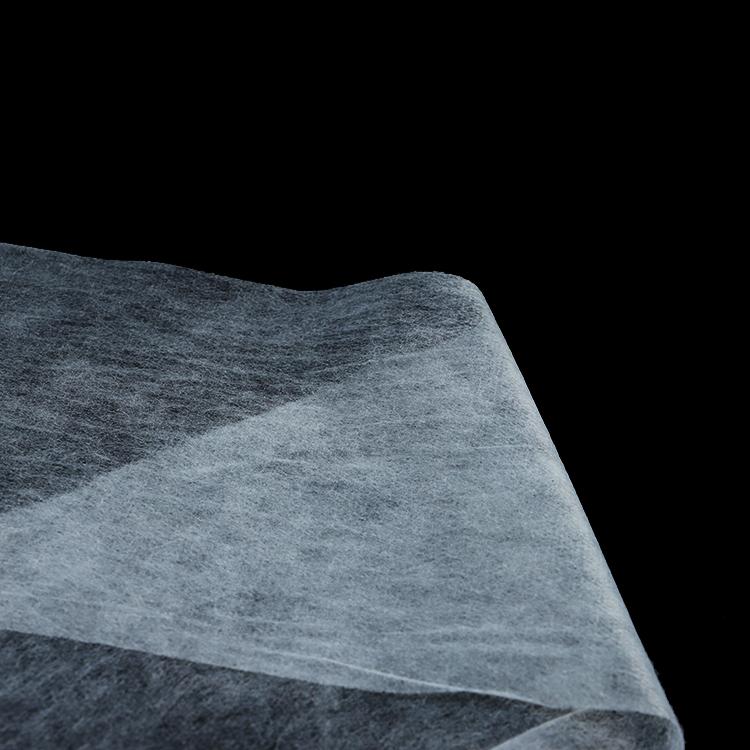

SSSspunbond polypropylene hydrophobic non woven fabric features: 1. Polypropyleneis the key component of the sterile quality of spunbond non woven fabrics. 2.Thematerial we of...

CATEGORY Soft hydrophilic non woven fabric APPLICATION Topsheet wrapping non woven fabric for medium grade diapers, pull-ups, sanitary napkin and under pads. WIDTH BASIC WEI...

1. SMMSnon woven fabrics (Spunbond + Meltblown + Meltblown + Spunbond Nonwovens), basicweight range: 10-100 gsm; width: 90mm-3200mm; it belongs to composite non wovenfabrics, which i...

Knitted frontal tape is widely used for baby diaper. It has the following features, 1. It is softer 2. Build secure closure system 3.Highly adhesive, colourful...

PP side tape features:PP side tape is made of polypropylene and 2-layer pressure-sensitive adhesive tape suitable for application on pp frontal tape. Mainly used for your economic diape...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China