Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-07

Unveiling the Secrets of Non Woven Factory in Diaper Production

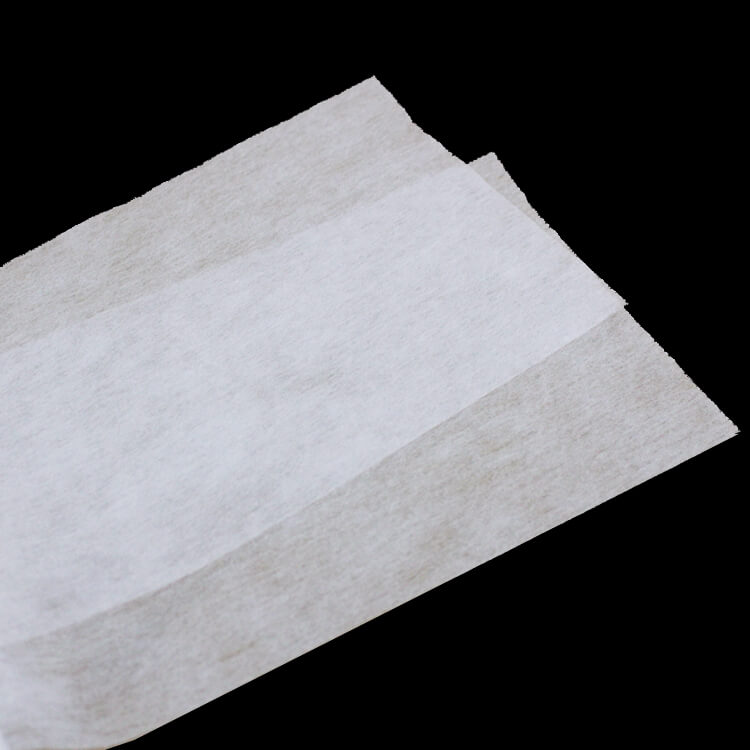

In the world of diaper production, non-woven fabric plays a crucial role in ensuring comfort and absorbency. Non-woven factories are responsible for producing this essential material. In this article, we will delve into the secrets behind the operations of a non-woven factory in the context of diaper production. From the production process to the quality control measures, we will explore how these factories contribute to the creation of high-quality diapers.

The production process of non-woven fabric in a diaper factory involves several intricate steps. It starts with the selection of raw materials, which typically include polyester, polypropylene, or a blend of both. These materials are then melted and extruded into fine fibers using specialized machinery. The fibers are then laid down on a conveyor belt in a random arrangement or bonded together through heat or pressure. This creates a web-like structure that is further processed to enhance its strength and thickness. Finally, the non-woven fabric is rolled onto spools or cut into sheets, ready to be used in diaper manufacturing.

To ensure the production of high-quality non-woven fabric, strict quality control measures are implemented in the factory. Throughout the production process, samples of the fabric are regularly taken and analyzed for various characteristics, such as tensile strength, absorbency, and uniformity. Advanced testing equipment is used to measure these properties accurately. Any deviations from the desired standards are immediately addressed to maintain consistency and reliability in the final product. Additionally, the factory adheres to international quality standards and certifications to further ensure the reliability of their non-woven fabric.

The non-woven factory is an integral part of diaper production, providing the essential material that guarantees comfort and absorbency. The production process involves several intricate steps, from selecting raw materials to processing the fabric into its final form. Stringent quality control measures are implemented throughout the process to maintain consistency and reliability in the fabric. By unveiling the secrets behind the operations of a non-woven factory, we gain a deeper understanding and appreciation for the craftsmanship that goes into producing high-quality diapers.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China