Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-07

Non-woven diapers have become increasingly popular due to their superior absorption, comfort, and affordability. The components of these diapers play a crucial role in ensuring their performance. In this article, we will delve into the technical know-how of non-woven diaper components, exploring the materials used, manufacturing processes involved, and the impact they have on the overall quality of the product.

The absorbent core is the heart of a non-woven diaper, responsible for absorbing and locking away moisture. It is typically made of a combination of wood pulp and superabsorbent polymers (SAPs). Wood pulp provides initial absorption, while SAPs have the ability to retain multiple times their weight in liquid. The key manufacturing process for the absorbent core is air-laid, where the wood pulp and SAPs are mixed and formed into a mat by utilizing airflow. This method ensures uniform distribution of materials, maximizing the absorbency of the core.

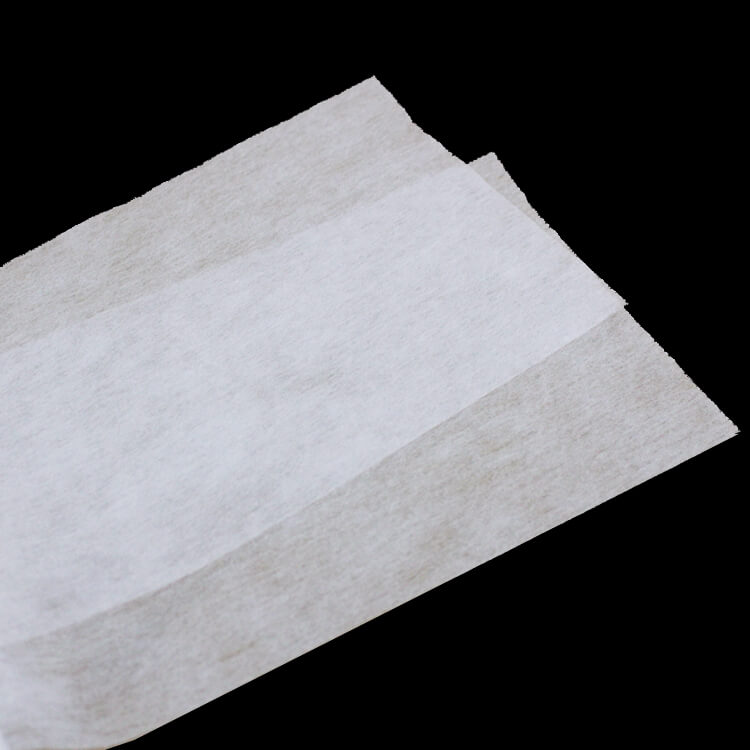

The top sheet is the layer that comes in direct contact with the baby's skin. It serves two primary functions - to allow liquids to pass through while keeping the surface dry, and to provide a soft and comfortable feel. Non-woven fabrics like spunbond polypropylene or hydrophobic fibers are commonly used to create the top sheet. These materials are chosen for their excellent liquid permeability and breathability. The manufacturing process involves spinning and bonding the fibers together to form a durable yet gentle fabric, which is then added to the diaper assembly.

The back sheet of a non-woven diaper acts as a barrier against leakage and ensures that the wetness is contained within the absorbent core. It is typically made of a thin, waterproof film or a laminated non-woven fabric. Polyethylene is commonly used for its water resistance properties. The manufacturing process involves extrusion coating or lamination, where a layer of polyethylene is applied to the non-woven fabric, creating a strong and impermeable back sheet. This process also ensures that the diaper remains breathable despite its waterproof nature.

In conclusion, understanding the technical aspects of non-woven diaper components is crucial for manufacturers to produce high-quality products. The absorbent core, top sheet, and back sheet each play vital roles in providing comfort, absorption, and leakage protection. By utilizing the right materials and employing efficient manufacturing processes, non-woven diapers can continue to meet the demands of parents worldwide, offering a reliable and convenient solution for their babies' needs.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China