Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-09-26

The Versatile Applications of SMMS Material in Diaper Production

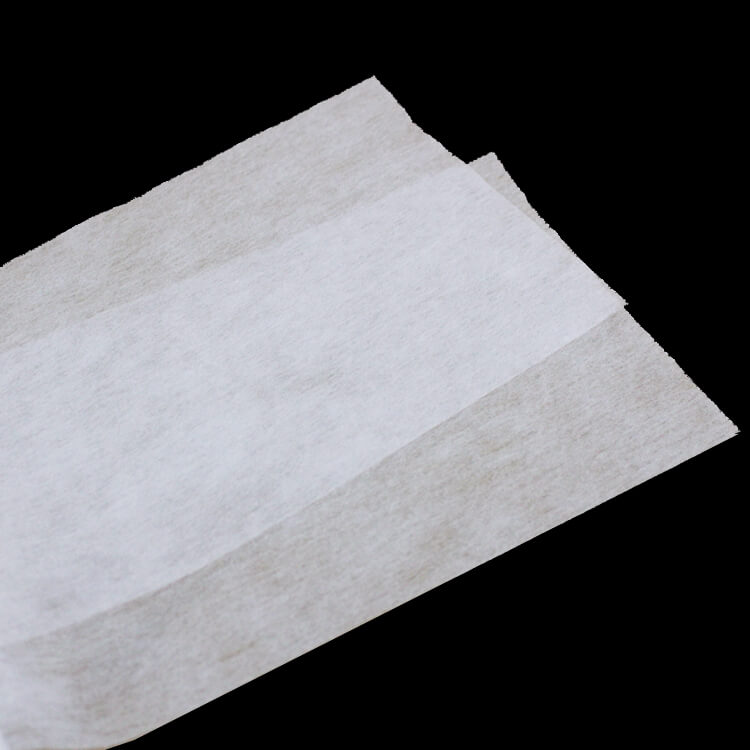

Super Meltblown Meltblown Spunbond (SMMS) material is a type of non-woven fabric that has gained significant attention in the diaper manufacturing industry. Its unique properties and versatility make it an ideal choice for various components of diapers. This article aims to explore the diverse applications of SMMS material in diaper production.

One of the key components in a diaper is the absorption layer, which is responsible for quickly absorbing and retaining liquid. SMMS material has a high absorbency rate due to its fine fiber structure and large surface area. It can effectively distribute and lock away moisture, keeping the baby's skin dry and comfortable. Furthermore, SMMS fabric has excellent liquid retention capabilities, preventing leakage and providing extended usage time for diapers.

A moisture barrier is essential in diapers to prevent leakage and maintain dryness. SMMS material demonstrates exceptional liquid impermeability due to its unique structure and hydrophobic properties. By incorporating SMMS fabric as a moisture barrier layer, diapers can effectively contain liquids and prevent them from seeping through the outer layer. This ensures maximum comfort and protection for babies, while also minimizing the risk of skin irritation and diaper rash.

The outer cover of diapers plays a vital role in providing comfort and breathability. SMMS material offers a soft and smooth texture, which enhances the overall comfort experienced by the baby. Its breathability properties allow for proper air circulation, reducing the likelihood of skin irritation and heat build-up. Additionally, SMMS fabric is lightweight and has a high tensile strength, ensuring durability and a snug fit without sacrificing comfort.

SMMS material has revolutionized the diaper production industry with its versatile applications. Whether as an absorption layer, moisture barrier, or outer cover, SMMS fabric provides exceptional performance in terms of absorbency, liquid impermeability, comfort, breathability, and durability. By incorporating SMMS material into diaper production, manufacturers can deliver high-quality products that prioritize the comfort, dryness, and protection of babies. As the demand for innovative and advanced diapers continues to grow, SMMS material will undoubtedly play a crucial role in meeting these requirements.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China