Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-09-14

Diaper pulp material, a byproduct of the diaper manufacturing process, has long been considered as waste. However, with the growing concern for environmental sustainability and the need for innovative solutions in various industries, harnessing the benefits of diaper pulp material in production has become an intriguing avenue to explore. This article will delve into the potential applications and advantages of utilizing diaper pulp material, and how it can contribute to a more sustainable and efficient production process.

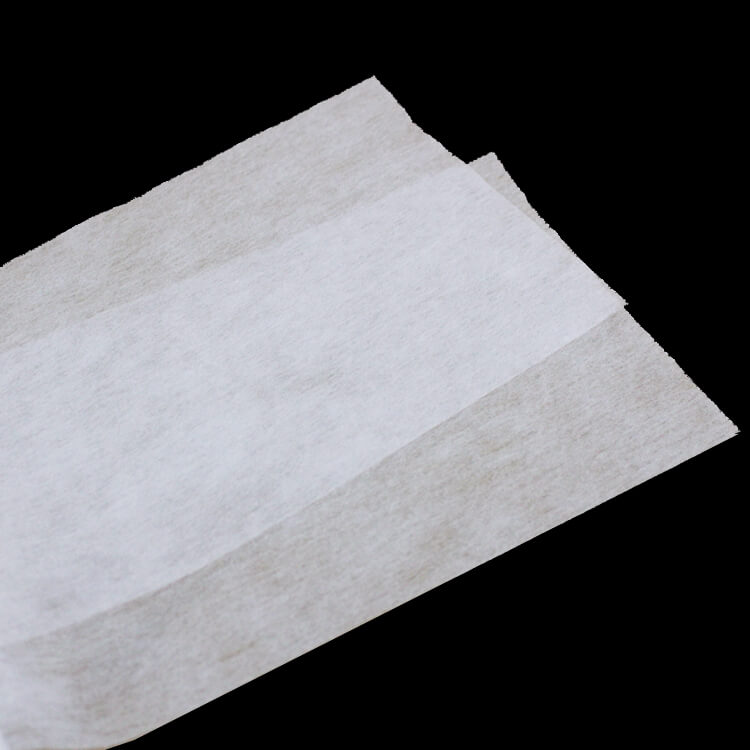

Before understanding the potential benefits of diaper pulp material, it's important to grasp its composition and properties. Diaper pulp material is primarily composed of cellulose fibers derived from wood pulp or recycled paper. These fibers possess excellent absorbency, softness, and liquid retention capabilities. Furthermore, the material is biodegradable and hypoallergenic, making it safe for various applications.

One of the key applications of diaper pulp material lies in the development of sustainable packaging solutions. Traditional packaging materials such as plastic and Styrofoam often contribute to environmental pollution and take centuries to decompose. In contrast, using diaper pulp material as packaging offers a renewable and eco-friendly alternative. Manufacturers can mold the material into protective foam-like structures that effectively cushion fragile products during transportation. Moreover, these packaging solutions can be easily recycled or composted, reducing waste and carbon footprint.

Diaper pulp material can also find valuable applications in the construction industry, specifically in reinforcing concrete. By incorporating diaper pulp fibers into the concrete mixture, the resulting composite material exhibits enhanced strength, durability, and crack resistance. The high absorbency and fiber reinforcement of the pulp material help to mitigate water-related issues such as cracking and shrinkage. Additionally, this sustainable alternative reduces the need for traditional reinforcing materials like steel, thereby reducing the overall environmental impact of construction projects.

In conclusion, harnessing the benefits of diaper pulp material in production offers numerous advantages in terms of sustainability and efficiency. From sustainable packaging solutions to reinforced concrete, the versatile properties of diaper pulp material make it a valuable resource in various industries. Embracing this innovation not only helps reduce waste but also contributes to the preservation of our environment. As the demand for eco-friendly solutions continues to rise, exploring and implementing the use of diaper pulp material is a step towards a greener future.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China