Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-09-11

Exploring the Uses of Diaper Making Raw Materials

Diapers are an essential item for infants and young children, providing a convenient and hygienic solution for managing their waste. The production of diapers involves the use of various raw materials that contribute to their absorbency, softness, and overall effectiveness. In this article, we will explore the different diaper making raw materials and their uses in creating high-quality diapers.

SAP is one of the most critical components of a diaper as it is responsible for its excellent absorbency. These polymers have the ability to absorb and retain large amounts of liquid, thereby keeping the baby's skin dry and comfortable. They are typically made from acrylic acid and are chemically treated to increase their absorption capacity. By incorporating SAP into the core of the diaper, manufacturers can ensure efficient moisture management, reducing the risk of rashes and irritation.

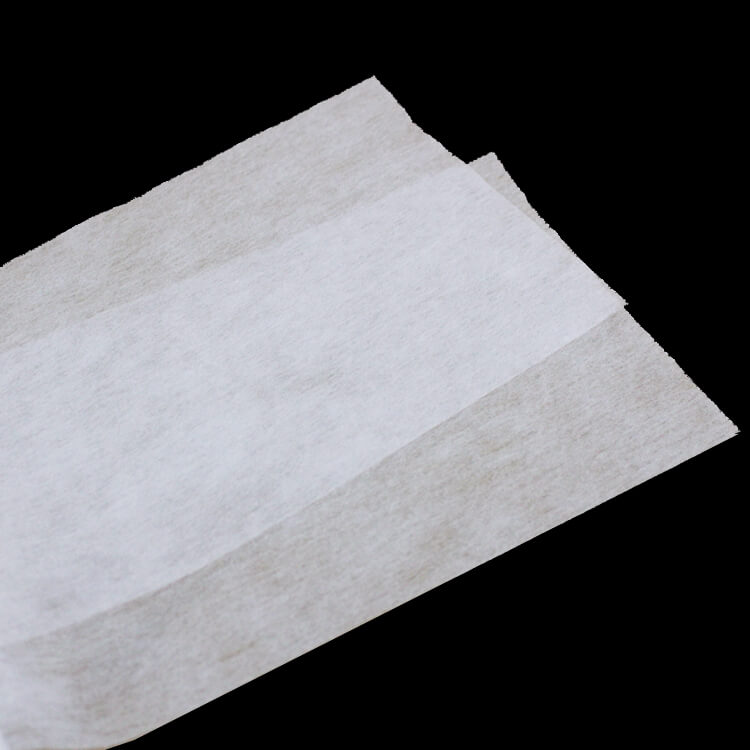

The outer and inner layers of a diaper need to be soft and gentle on the baby's delicate skin. This is where nonwoven fabrics come into play. Nonwoven fabrics are made from synthetic fibers that are bonded together through mechanical, thermal, or chemical processes. These fabrics are highly versatile and can be engineered to be incredibly soft and breathable. By using soft nonwoven fabrics in diapers, manufacturers can provide a comfortable and irritation-free experience for babies.

Elastic components are crucial for providing a snug fit and preventing leakage. Diapers often feature elastic bands around the waist and leg openings, ensuring a secure and comfortable fit for the baby. These elastic components are typically made from natural rubber or synthetic materials like spandex. The elasticity allows the diaper to adapt to the baby's movements while maintaining a tight seal, preventing any leaks or accidents. By incorporating elastic components, manufacturers can enhance the overall performance and reliability of the diaper.

Diaper making raw materials play a significant role in creating high-quality and effective diapers. Superabsorbent polymers ensure excellent moisture management, keeping the baby's skin dry and comfortable. Soft nonwoven fabrics provide a gentle and irritation-free experience, while elastic components ensure a secure and leak-proof fit. By understanding the uses of these raw materials, manufacturers can continue to innovate and improve the design and performance of diapers, ultimately benefiting both parents and babies alike.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China