Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-28

Driving Diaper Innovation through Spun Bonded Nonwoven Solutions

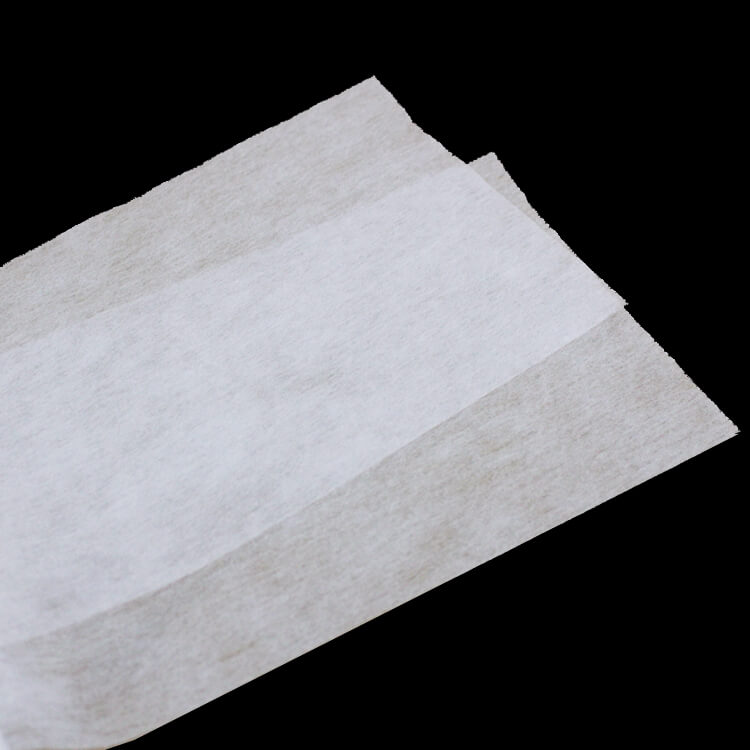

In recent years, the use of diapers has become increasingly prevalent in our society, both for infants and adults. As the demand for more efficient and comfortable diapers grows, so does the need for innovative solutions in diaper manufacturing. One such solution that has gained significant attention is the use of spun bonded nonwoven fabrics. These fabrics offer unique properties that can revolutionize the diaper industry, providing benefits such as enhanced absorbency, breathability, and softness. This article delves into the various ways in which spun bonded nonwoven solutions are driving diaper innovation.

One of the primary concerns when it comes to diapers is their ability to effectively absorb liquids and keep the wearer dry. Spun bonded nonwoven fabrics have proven to be highly effective in enhancing the absorbency of diapers. These fabrics can be designed with specific fiber configurations and pore sizes, allowing for optimal fluid retention. The uniform distribution of fibers within the fabric ensures that liquids are absorbed quickly and evenly across the diaper, preventing leakage and discomfort. Moreover, the high surface area of the fabric provides a larger area for liquid absorption, further improving its performance.

Additionally, spun bonded nonwoven fabrics can be treated with hydrophilic agents during the manufacturing process. These agents help to attract and spread liquid throughout the fabric, maximizing its absorbent capacity. The combination of specialized fiber designs and hydrophilic treatments makes spun bonded nonwoven fabrics an ideal choice for enhancing the absorbency of diapers.

Another crucial aspect of diaper design is breathability and comfort. Traditional diapers often trap heat and moisture, leading to skin irritation and discomfort for the wearer. Spun bonded nonwoven solutions offer excellent breathability, allowing air to circulate freely through the fabric. This helps to keep the skin dry and cool, reducing the risk of diaper rashes and other skin irritations.

Furthermore, the softness of spun bonded nonwoven fabrics enhances the overall comfort of diapers. The fabrics are gentle on the delicate skin of infants and adults alike, providing a soothing experience. The smooth surface of the fabric minimizes friction and irritation, making it an ideal choice for those with sensitive skin. By incorporating spun bonded nonwoven solutions into diaper manufacturing, companies can prioritize both breathability and comfort, ensuring a better experience for users.

In recent years, there has been a growing emphasis on sustainability in various industries, including diaper manufacturing. Spun bonded nonwoven fabrics offer several advantages in this regard. Firstly, these fabrics can be produced using recycled materials, reducing the reliance on virgin resources. This helps to minimize the environmental impact associated with diaper production.

Additionally, spun bonded nonwoven solutions can be designed to have a longer product life cycle, making them more durable than traditional fabrics. This not only reduces the frequency of diaper changes but also leads to cost savings for consumers. Moreover, the lightweight nature of spun bonded nonwoven fabrics reduces transportation costs and carbon emissions during distribution.

Spun bonded nonwoven solutions are revolutionizing the diaper industry by driving innovation in absorbency, breathability, comfort, sustainability, and cost efficiency. These fabrics offer enhanced absorbency through specialized fiber configurations and hydrophilic treatments, ensuring optimal liquid retention. The breathability and softness of the fabrics provide a more comfortable experience for diaper wearers, while also reducing the risk of skin irritations. Furthermore, the use of recycled materials and longer product life cycles contribute to sustainability efforts and cost savings. As the demand for more efficient and eco-friendly diapers continues to grow, spun bonded nonwoven solutions will play a crucial role in shaping the future of diaper manufacturing.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China