Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-07

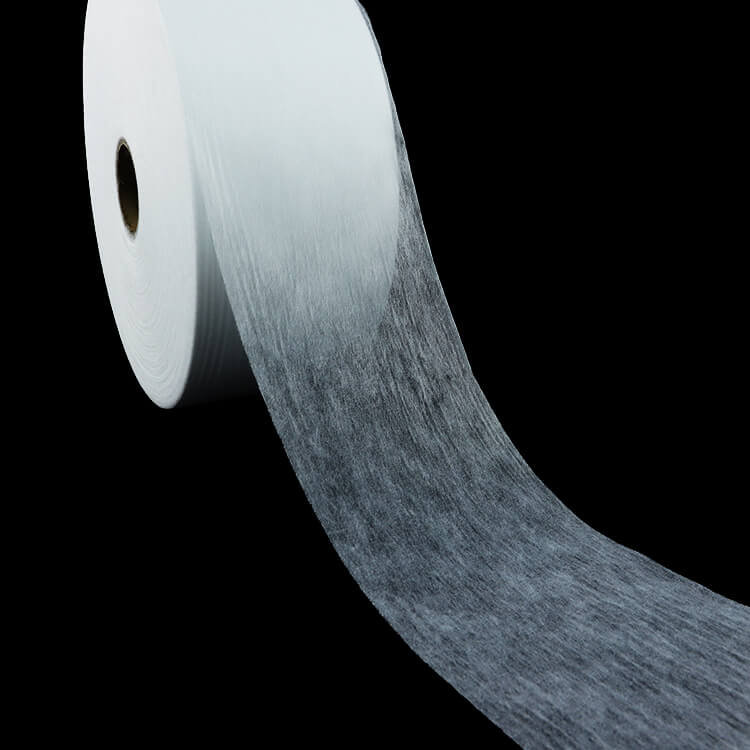

Unveiling the Benefits of Spunbond Non Woven in Diaper Production

Spunbond non woven fabric has revolutionized the diaper production industry in recent years. This innovative material has proven to be superior to traditional fabrics in terms of performance, comfort, and sustainability. In this article, we will delve into the benefits of using spunbond non woven in diaper production, exploring its advantages in terms of absorption, breathability, and eco-friendliness.

One of the major advantages of spunbond non woven fabric in diaper production is its enhanced absorption capabilities. The unique structure of this fabric allows for better liquid retention, preventing leakage and keeping the baby dry for longer periods. The hydrophilic nature of spunbond non woven ensures efficient liquid distribution throughout the fabric, reducing the chance of discomfort or skin irritation for the baby. Furthermore, the high absorbency rate of spunbond non woven enables manufacturers to create thinner and more lightweight diapers without compromising on performance.

Breathability is another key aspect where spunbond non woven fabric excels. Its porous structure allows for better air circulation, reducing the risk of diaper rash and maintaining a comfortable temperature for the baby's delicate skin. The ability of spunbond non woven to wick away moisture quickly also contributes to better breathability, as it helps to prevent the build-up of humidity inside the diaper. The combination of enhanced absorption and improved breathability makes spunbond non woven an ideal choice for manufacturing diapers that prioritize the baby's comfort and well-being.

In addition to its performance benefits, spunbond non woven fabric is also highly sustainable and eco-friendly. Unlike traditional fabrics that require extensive water consumption and energy-intensive processes for production, spunbond non woven can be manufactured using a dry process with minimal water usage. The fabric is also 100% recyclable, reducing waste and the strain on landfills. Furthermore, the lightweight nature of spunbond non woven allows for efficient transportation, resulting in a lower carbon footprint during distribution. By incorporating spunbond non woven into diaper production, manufacturers can contribute to a more sustainable and environmentally conscious industry.

The utilization of spunbond non woven in diaper production offers a myriad of benefits ranging from enhanced absorption and improved breathability to eco-friendliness. This innovative fabric not only ensures superior performance and comfort for babies but also promotes sustainable manufacturing practices. As the demand for high-quality and eco-friendly diapers continues to rise, the incorporation of spunbond non woven fabric in the industry is expected to increase significantly. By embracing this technology, manufacturers can stay ahead of the competition while contributing to a healthier and more sustainable future for the next generation.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China