Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-01

Diapers play a crucial role in the lives of infants and young children, providing comfort, hygiene, and convenience. Over the years, diaper manufacturing has seen significant advancements in technology and materials. One such innovative material that has revolutionized the industry is laminated spunbond fabric. This fabric has opened up new possibilities in diaper production, offering improved performance and enhanced features. In this article, we will explore the innovative use of laminated spunbond fabric in diaper manufacturing.

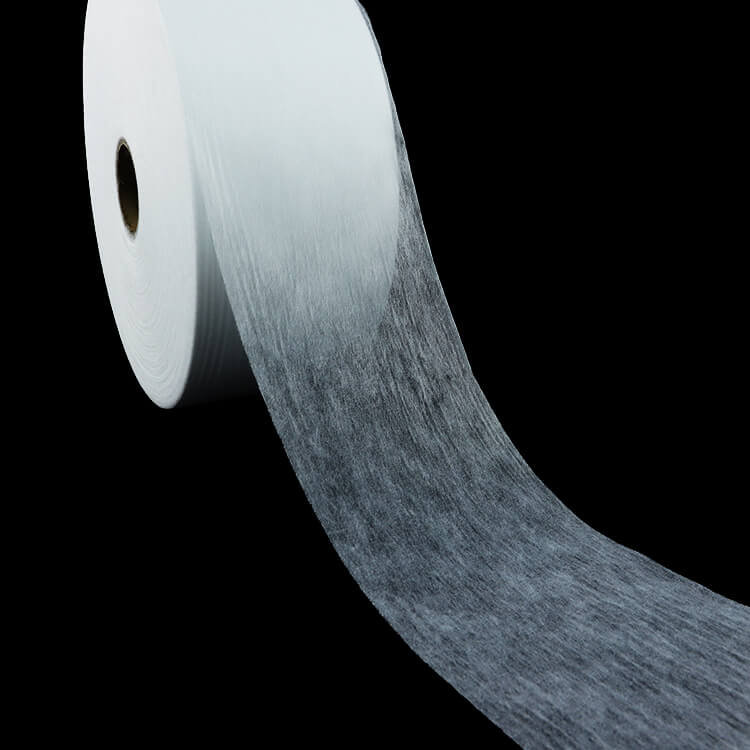

One of the key advantages of using laminated spunbond fabric in diapers is its enhanced liquid absorption properties. The fabric is constructed by combining multiple layers of spunbond material, which are then bonded together to create a strong and durable structure. This multi-layered design allows for better retention and distribution of fluids, ensuring that the diaper remains dry and comfortable for extended periods. Additionally, the laminated surface helps to prevent leakage, providing an extra layer of protection for the baby's skin.

Babies have delicate skin that requires proper ventilation to prevent irritation and rashes. Laminated spunbond fabric offers improved breathability compared to traditional diaper materials. The fabric is designed with micro-pores that allow air to circulate freely, reducing the risk of excessive moisture build-up. This enhanced breathability helps to keep the baby's skin dry, cool, and comfortable, minimizing the chances of diaper rash and other skin irritations. Moreover, the laminated surface ensures that the diaper remains soft and gentle against the baby's sensitive skin.

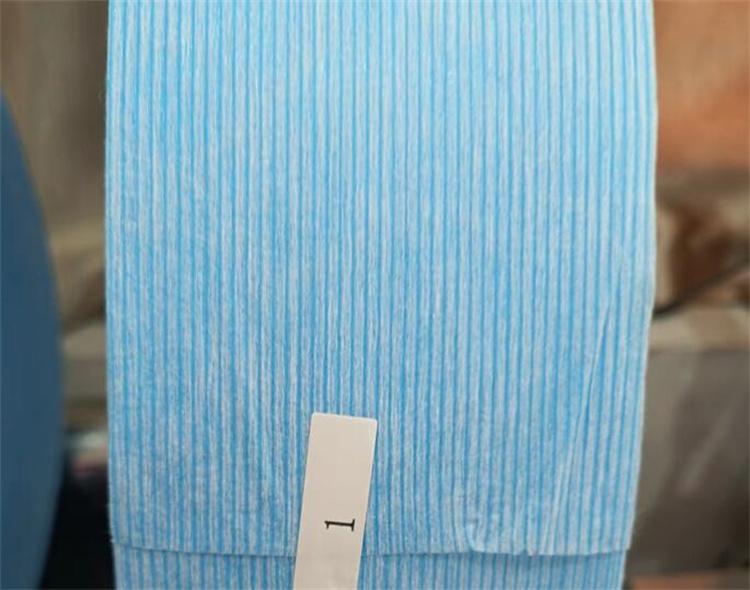

Laminated spunbond fabric provides diaper manufacturers with a wide range of design options. The fabric can be easily customized to meet specific requirements in terms of size, shape, and absorbency levels. The versatility of the material allows for the integration of various features, such as wetness indicators, elasticized waistbands, and resealable tabs. Furthermore, the fabric can be printed with attractive patterns and designs, making diapers more visually appealing. This versatility not only enhances the overall functionality of the diaper but also adds an element of fun and style.

In conclusion, the innovative use of laminated spunbond fabric in diaper manufacturing has brought about significant improvements in performance, comfort, and aesthetics. With its enhanced liquid absorption properties, improved breathability, and versatile design options, this fabric has proven to be a game-changer in the industry. Diapers made with laminated spunbond fabric offer better protection against leaks, keep the baby's skin dry and comfortable, and provide a customizable and visually appealing product. As technology continues to advance, we can expect further innovations in diaper manufacturing, ensuring the well-being and happiness of our little ones.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China