Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Wet wipes

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

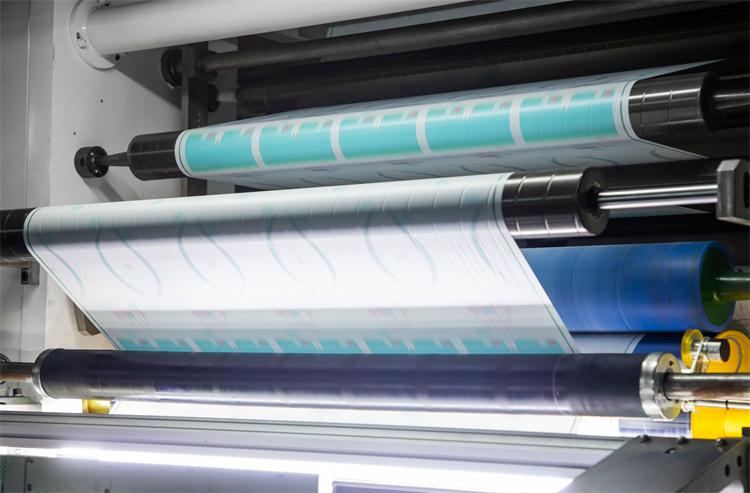

Plain Spunlace Nonwoven Fabric

It is made of plant cellulose, poly fiber, or viscose, polyester, PLA, bamboo with hydroentangle technology.It is good at nice veins looking, softness and low-lint.

Dot Embossed Spunlace Nonwoven Fabric

It is cross lapping under hydroentangle technology.Strength at cross direction and machine direction is about 1:1.5.It is good at maintaining shaped, higher friction and better decontaminability.

Origin-color Bamboo Spunlace Nonwoven Fabric

It is made of natural bamboo and original color is well kept.Degradable, no whitening, natural and eco-friendly. Fabric is good at gloss, softness and being fine and smooth.

Mesh Spunlace Nonwoven Fabric

It is made of plant cellulose, poly fiber, or viscose, polyester, PLA, bamboo with hydroentangle technology.This product with clear meah is good at softness, absorption and breathability.

Tencle Plain Spunlace Nonwoven Fabric

It is made of woodpulp from plants, under hydroentangle technology.Fabric is natural, degradable. It is good at nice veins looking, softness, smooth and absorption.

|

DESCRIPTION OF SPUNLACE NONWOVEN FABRIC |

|

|

Technology |

Spunlace, Hydroentanglement, Water-jet |

|

Web Forming |

Parallel lapping, Cross lapping |

|

Composition |

Viscose (Rayon)+Polyester (PET) (+ES), Bamboo, PLA, Cotton, Woodpulp+PP/PET/Viscose, etc. |

|

Specific Ratio |

Customized |

|

Structure |

Plain, Mesh(perforated, apertured, hole), Dot Embossed, Jacquard, EF, Herring Bond |

|

Printing |

Wave line, Diamond, Dyed, as customized |

|

Color |

White, Green, Blue, etc. |

|

Width |

6-320cm |

|

Weight |

25-100gsm |

|

Roll Length |

500-3,000 meters |

|

MOQ |

3,000 KGS per item |

|

Leading Time |

Within 15~30 days upon receipt of deposit and confirmation of samples |

|

Annual Production Capacity |

About 70,000 tons |

|

Payment Terms |

T/T, L/C, D/P, etc. |

|

Customization Service |

Available |

|

Converting |

In roll, Folded sheet, Perforated roll, Jumbo roll, etc. |

|

Characteristics |

Customized as the application and requirements, some characteristics as follow: 1. Flushable, good dispersibility 2. Washable, long-lasting 3. Soft touch, excellent breathability 4. Eco-friendly, biodegradable 5. Super absorbent 6. Good tensile strength |

|

Package |

PE film, Shrink film, Poly bag, Opp bag, Carton, as requirement. |

|

Application |

Beauty care, Medical care, Wipes, Diapers, Sanitary napkins, Alcohol swab, Toilet wipes, more... |

Air through non woven fabric is a kind ofhot air bonding (hot rolling, hot air) non woven fabric. Hot air non woven isto use the hot air on the drying equipment to penetrate the fi...

1. Spunlace non woven fabric is made by viscose and polyester. 2.Spunlace non woven fabric can be cross type or parallel type. 3.Spunlace non woven fabric can be plain or dot. 4.Ap...

Thermal Bond Non Woven Fabric Raw Material forSanitary Napkin Production thermal bond non woven fabric,thermal bond nonwoven,thermal bond non woven fabric price,Sanitary nap...

Today WEIHONGLAI load raw material for producing diapers for the customer in Chile. They mix all raw materials in one 40HQ, such as hydrophilic spunbond non woven fabric, velcro si...

In the highly competitive market for personal care products in Brazil, customers are always looking for ways to stand out and gain an edge over their competitors. One way to do thi...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China