Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-06-05

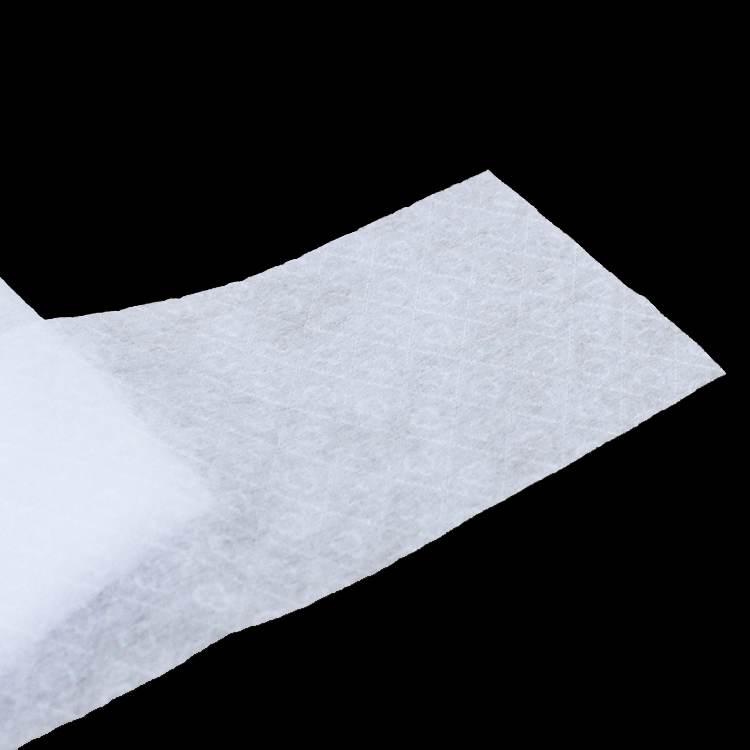

Hot air non woven ES fiber is a popular material used in the manufacturing of baby diapers. This synthetic fabric is known for its excellent absorption and soft texture, which makes it a perfect choice for producing high-quality disposable diapers. In this article, we will explore the properties and benefits of hot air non woven ES fiber and how it can be used to improve the quality of baby diapers.

Hot air non woven ES fiber is created using a specialized process that involves heating and melting synthetic fibers such as polypropylene and polyethylene. The fibers are then spun into an intricate web-like structure that is held together by heat and pressure. This unique structure gives hot air non woven ES fiber its distinctive features, including high absorption and permeability, softness, and durability. The material is also resistant to tears and punctures, making it ideal for use in baby diapers where robustness is essential.

Manufacturers use hot air non woven ES fiber in baby diapers because it provides several important benefits. Firstly, the material is incredibly absorbent, so it can hold large amounts of liquid without leaking. Secondly, it is highly permeable, which means it allows air to flow through the fabric and keeps the baby's skin dry and comfortable. Thirdly, the soft texture of the material reduces the risk of diaper rash and irritation. Additionally, the high durability of hot air non woven ES fiber ensures that the diaper remains intact, even during prolonged use.

Hot air non woven ES fiber is a versatile material that can be easily incorporated into the production process for baby diapers. Manufacturers start by creating the non-woven fabric using the hot air technique. The fabric is then cut and shaped into specific sizes based on the diaper's design. Next, they layer the hot air non woven ES fiber with other materials such as absorbent pads, elastic bands, and fasteners. These layers are sealed together using heat and pressure to create a secure and comfortable fit for the baby. Finally, the diapers are packaged and sent to retailers for distribution.

In conclusion, hot air non woven ES fiber is an essential material used in the manufacturing of high-quality baby diapers. Its unique properties of absorbency, permeability, softness, and durability make it ideal for use in disposable diapers. Additionally, the process of creating this fabric is energy-efficient and environmentally friendly, making it a sustainable choice for diaper production. With its many benefits, it's no wonder that hot air non woven ES fiber remains a top-choice material for baby diapers.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China