Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-07

Unveiling the Applications of Non-Woven Spunbond Polypropylene in Diaper Manufacturing

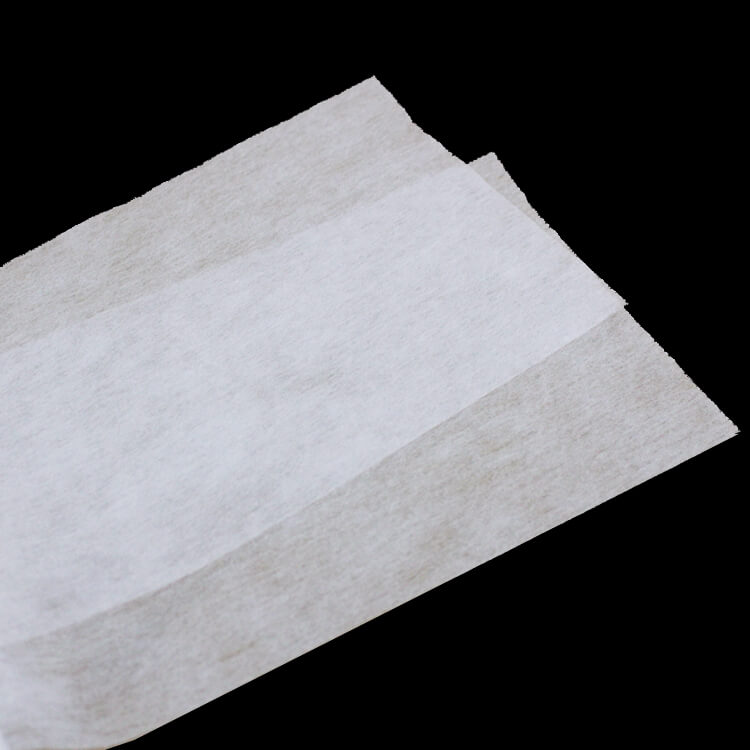

Diapers are an essential commodity for infants and toddlers, providing comfort and protection. The manufacturing process of diapers involves the use of various materials to ensure their absorbency and leak-proof nature. Non-woven spunbond polypropylene has emerged as a popular choice due to its unique properties and versatility. This article aims to explore the applications of non-woven spunbond polypropylene in diaper manufacturing.

One of the primary reasons for utilizing non-woven spunbond polypropylene in diaper manufacturing is its exceptional absorbency. This material has a high liquid retention capacity, allowing it to quickly absorb and lock away moisture. The fibers in non-woven spunbond polypropylene create a porous structure that facilitates efficient liquid absorption, keeping the baby's skin dry and preventing rashes or irritation.

In addition to its absorbency, non-woven spunbond polypropylene also offers excellent fluid distribution properties. The material distributes the absorbed liquid evenly throughout the diaper, ensuring maximum utilization of its absorbent core. This feature enhances the overall effectiveness of the diaper, minimizing the risk of leakage and improving the baby's comfort.

Baby's skin is delicate and sensitive, requiring soft and gentle materials to prevent discomfort or irritation. Non-woven spunbond polypropylene exhibits excellent softness, making it an ideal choice for the top sheet and inner layers of diapers. The fine fibers of the material create a smooth surface that feels gentle against the baby's skin, offering a comfortable experience.

Furthermore, non-woven spunbond polypropylene is highly breathable, allowing air circulation within the diaper. This breathability helps in reducing the risk of diaper rash and maintaining optimal skin health for the baby. The softness and breathability of this material provide a comfortable environment for the baby, ensuring a happy and contented experience.

In addition to its performance benefits, non-woven spunbond polypropylene also offers cost-effectiveness and sustainability advantages in diaper manufacturing. The material is relatively inexpensive compared to alternatives, making it a cost-effective choice for mass production. Its availability in large quantities and ease of processing further contribute to its affordability.

Moreover, non-woven spunbond polypropylene is recyclable and environmentally friendly. It can be easily recycled and used in various applications, reducing waste and promoting sustainability. The use of this material aligns with the growing demand for eco-friendly diaper options, satisfying both consumer preferences and environmental concerns.

Non-woven spunbond polypropylene has revolutionized diaper manufacturing with its enhanced absorbency, softness, cost-effectiveness, and sustainability. The utilization of this material ensures improved comfort, protection, and overall quality of diapers. As the demand for high-performance and eco-friendly products continues to rise, non-woven spunbond polypropylene remains an invaluable component in the diaper industry, paving the way for innovative and responsible solutions.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China