Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-19

Exploring the Usages of PP Spunbond in Producing Diapers

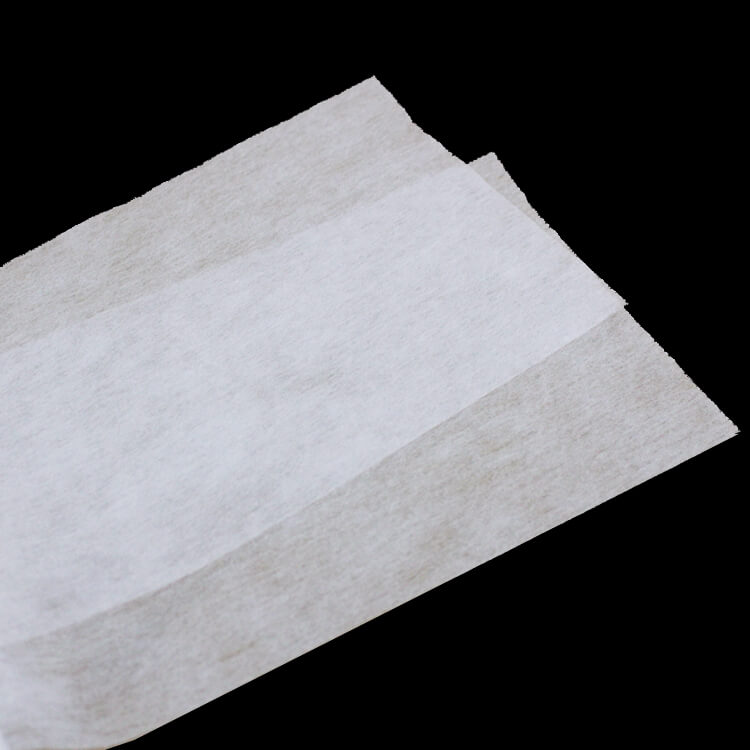

The production of diapers has evolved significantly over the years, with manufacturers constantly exploring innovative materials and technologies. One such material that has gained prominence is polypropylene (PP) spunbond. PP spunbond is a nonwoven fabric made from long staple fibers. It possesses numerous qualities that make it an ideal choice for diaper production. This article aims to delve into the usages of PP spunbond in producing diapers, highlighting its benefits and applications.

One of the primary reasons PP spunbond is favored in diaper production is its exceptional absorbency and moisture management capabilities. The fabric is designed to wick away moisture from the baby's skin, keeping it dry and comfortable. The unique structure of PP spunbond allows it to absorb and distribute liquid evenly, preventing leaks and ensuring optimal hygiene. Moreover, its ability to quickly lock in moisture helps to reduce the risk of diaper rash, providing a soothing and protective layer for the baby's delicate skin.

When it comes to diapers, the comfort of the baby is of utmost importance. PP spunbond fabric offers a high level of softness, making it gentle on the baby's skin. The smooth texture of the fabric ensures minimal friction, reducing the likelihood of irritation or rashes. Additionally, PP spunbond is breathable, allowing air circulation to keep the baby's bottom cool and dry. The superior softness and comfort provided by PP spunbond contribute to a more pleasant experience for both babies and parents alike.

PP spunbond is known for its exceptional durability, making it a cost-effective choice for diaper manufacturers. The fabric can withstand repeated use, maintaining its strength and integrity even after multiple washes. This longevity minimizes the need for frequent diaper replacements, resulting in long-term cost savings for parents. Additionally, the ease of manufacturing and affordability of PP spunbond contribute to its cost-effectiveness, making it an attractive option for both large-scale diaper production and individual consumers.

PP spunbond has revolutionized the diaper manufacturing industry with its impressive attributes. Its absorbency, moisture management capabilities, softness, and durability make it an excellent choice for producing high-quality diapers. The fabric ensures optimal comfort and hygiene for babies while providing convenience and cost-effectiveness for manufacturers and parents. As technology continues to advance, it is likely that PP spunbond will play an even more significant role in shaping the future of diaper production.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China