Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-09-11

The global diaper market has been witnessing significant growth over the years, driven by factors such as rising birth rates, increasing consumer disposable income, and growing awareness about hygiene and sanitation. As a result, diaper manufacturers are constantly seeking innovative materials to enhance the performance and comfort of their products. In recent times, non-woven spun-bonded fabric has emerged as a promising material for diaper production, offering several advantages over traditional woven fabrics.

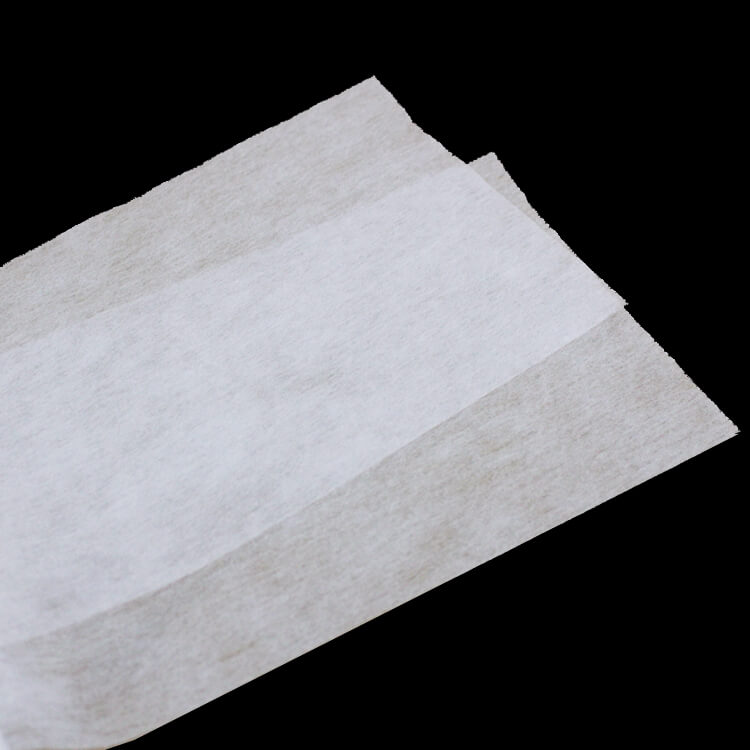

Non-woven spun-bonded fabric is manufactured through a process that entangles fibers together, resulting in a porous structure with excellent absorbency properties. This makes it an ideal choice for the core layer of diapers, as it can efficiently capture and retain liquid, keeping the baby's skin dry and comfortable. Furthermore, the porous structure allows for rapid fluid dispersion, minimizing the risk of leakage. Diaper manufacturers can leverage these characteristics to create high-performance diapers that provide long-lasting dryness and prevent skin irritation.

One of the key requirements for baby diapers is softness against the delicate skin. Non-woven spun-bonded fabric offers a soft and smooth texture, ensuring a gentle touch on the baby's skin. Additionally, the fabric has inherent breathability, allowing for air circulation and reducing the risk of diaper rash. This is particularly important in hot and humid climates, where moisture build-up can lead to discomfort and skin problems. By incorporating non-woven spun-bonded fabric in diaper production, manufacturers can prioritize the comfort and well-being of babies.

Non-woven spun-bonded fabric is also advantageous in terms of cost-effectiveness and sustainability. Compared to woven fabrics, it can be produced at a lower cost, primarily due to the automated manufacturing process and reduced material waste. The lightweight nature of non-woven spun-bonded fabric further contributes to cost savings in terms of transportation and storage. Moreover, the fabric is recyclable and can be repurposed for various applications, making it an environmentally-friendly choice for diaper manufacturers.

In conclusion, non-woven spun-bonded fabric offers significant market potential in the production of diapers. Its superior absorbency, softness, breathability, cost-effectiveness, and sustainability make it a compelling choice for manufacturers seeking to enhance the performance and comfort of their products. As the global diaper market continues to expand, it is crucial for manufacturers to explore and capitalize on the benefits offered by non-woven spun-bonded fabric to stay competitive in the industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China