Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-23

Application of Raw Materials in Baby Diaper Film

The production of baby diapers involves the utilization of various raw materials to create an effective and comfortable diaper film. These raw materials play a crucial role in ensuring the absorbency, softness, and durability of the diaper. Understanding the application of raw materials in baby diaper films is essential for manufacturers to produce high-quality products.

To ensure effective absorption of liquids, the absorbent core materials used in baby diaper films are crucial. Superabsorbent polymers (SAP) are commonly employed due to their ability to absorb and retain large quantities of liquid. SAPs are incorporated into the core of the diaper film, where they can lock away moisture and prevent leakage. Additionally, fluff pulp, which is made from wood fibers, is used in combination with SAP to enhance absorbency and add bulk to the diaper film. Together, these materials provide excellent absorption capabilities, keeping babies dry and comfortable.

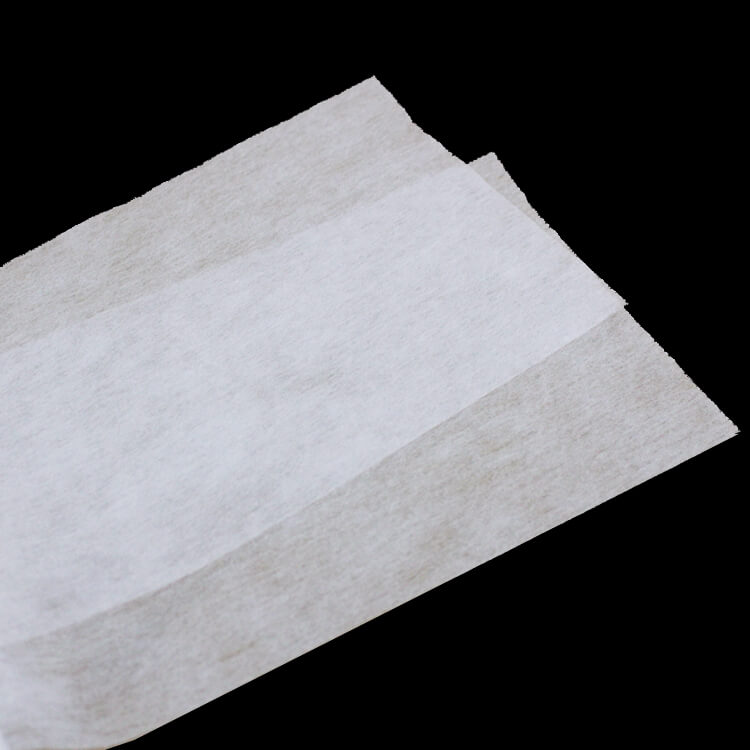

The comfort of a baby diaper film is of utmost importance, and this is achieved through the use of softness enhancers. Nonwoven fabrics, such as spunbond and meltblown fabrics, are commonly used as the top and back layers of the diaper film. These fabrics provide a soft and gentle touch to the baby's skin and allow for breathability to prevent rashes and irritation. Furthermore, elastic materials, such as elastic threads or films, are incorporated into the diaper film to provide a snug fit and flexibility, allowing the baby to move comfortably without restrictions.

The outer layer of a baby diaper film is responsible for providing a barrier against leakage and ensuring the diaper remains intact during use. Polyethylene or polypropylene films are commonly used as the outer layer due to their excellent waterproof properties. These films effectively prevent liquids from seeping through the diaper, keeping the baby's clothes and surrounding environment dry. Additionally, adhesive materials are applied to the outer layer to provide a secure closure system, allowing easy fastening and adjustment of the diaper.

Overall, the application of raw materials in baby diaper films is crucial for the production of high-quality and functional products. Absorbent core materials, softness and comfort enhancers, and outer layer protection all work together to create a diaper film that is absorbent, soft, comfortable, and leak-proof. Manufacturers need to carefully select and combine these raw materials to ensure the best performance and comfort for babies.

In conclusion, the proper selection and utilization of raw materials significantly contribute to the overall quality and performance of baby diaper films. The continuous improvement and innovation in raw materials enable manufacturers to produce more advanced and comfortable diapers, catering to the needs of both parents and babies. The application of raw materials in baby diaper films plays a vital role in ensuring the well-being and comfort of infants, making diaper changing a hassle-free experience for parents.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China