Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-06

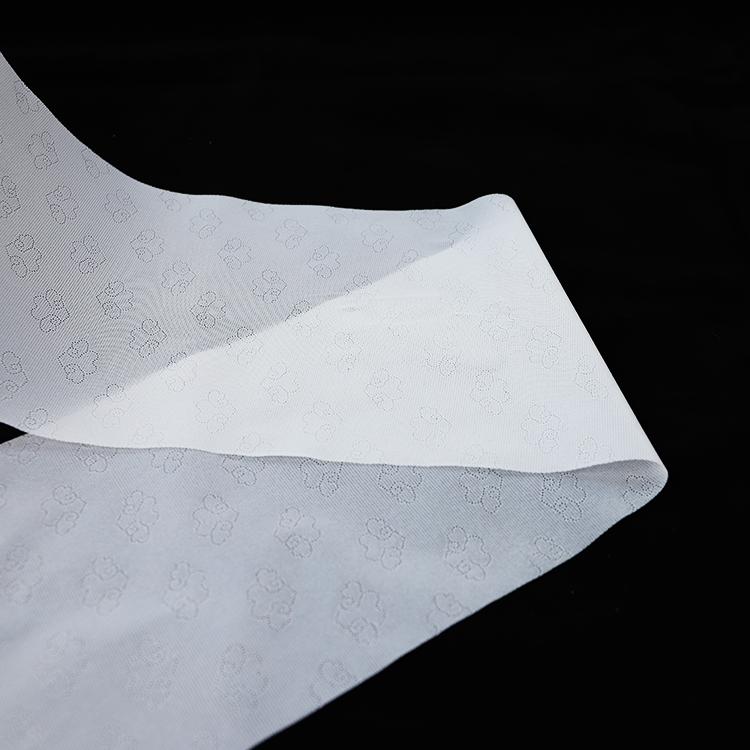

Perforated PE film topsheet is mainly used in the packaging of hygienic food industry, such as diapers, sanitary napkins and other sanitary products. These Perforated PE film topsheets are mainly made of PE. During the production process of Perforated PE film topsheet, PE plastic particles and Additives are put into the mixing tank for mixing and stirring, and then manufactured through a series of processing processes such as heating, film making, cutting, punching and winding.

The existing Perforated PE film topsheet production raw material mixing device mostly puts the production raw materials and additives directly into the mixing tank, and drives the stirring rod to stir and mix through the stirring motor. Putting it into the mixing tank will cause layered accumulation between the production raw materials and additives. Stirring in this case will lead to the difficulty of mixing and stirring between the production raw materials and additives. For this reason, Lin Meijing, Zeng Jinhui, and Xin Longchao A raw material mixing equipment for perforated membrane production is proposed.

The Perforated PE film topsheet raw material mixing equipment includes a mixing tank, the end of the mixing tank is fixed with a stirring motor, and the inner wall of the mixing tank is connected with a stirring shaft, and the end of the stirring shaft passes through the mixing tank and is connected with the stirring motor. The output end is connected and fixed, the outer wall of the stirring shaft has a symmetrical structure, and the auger blades have multiple stirring plates. The top of the stirring barrel is fixed with a feeding pipe, and the top of the feeding pipe is fixed with a feeding barrel. The inner wall of the feed pipe is fixed with a fixed frame, and the inner wall of the fixed frame is rotatably connected with a rotating shaft. The lower ends are fixed with bevel gears, and the two bevel gears mesh with each other. The upper end of the rotating shaft extends to the inside of the feeding barrel, and the outer wall of the rotating shaft is fixed with a plurality of stirring rods, and the stirring rods are located inside the feeding barrel.

The beneficial effects of the Perforated PE film topsheet production raw material mixing equipment are:

A. The stirring motor is used to drive the stirring shaft and the rotating shaft to rotate, and the rotating shaft is used to drive the stirring rod and the auger blade to rotate, and the agitating rod is used to mix and stir the mixture inside the feeding barrel, and it is transported to the inside of the mixing barrel through the auger blade, so that Avoid layered accumulation between raw materials and additives, which increases the difficulty of mixing.

B. When the mixture flows into the mixing tank through the feeding pipe, it is blocked by the distribution plate, and the mixture will disperse and flow to the four sides of the mixing tank along the grooves formed by the combination of multiple distribution plates, so that the mixing When the material flows into the mixing tank, it is more uniformly dispersed and less piled up, so it is more convenient to stir the mixture.

C. By setting the sealing sleeve and the sealing cover, the bevel gear can be protected to prevent the mixture from flowing into the tooth grooves on the bevel gear, which will increase the wear of the bevel gear.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China