Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-27

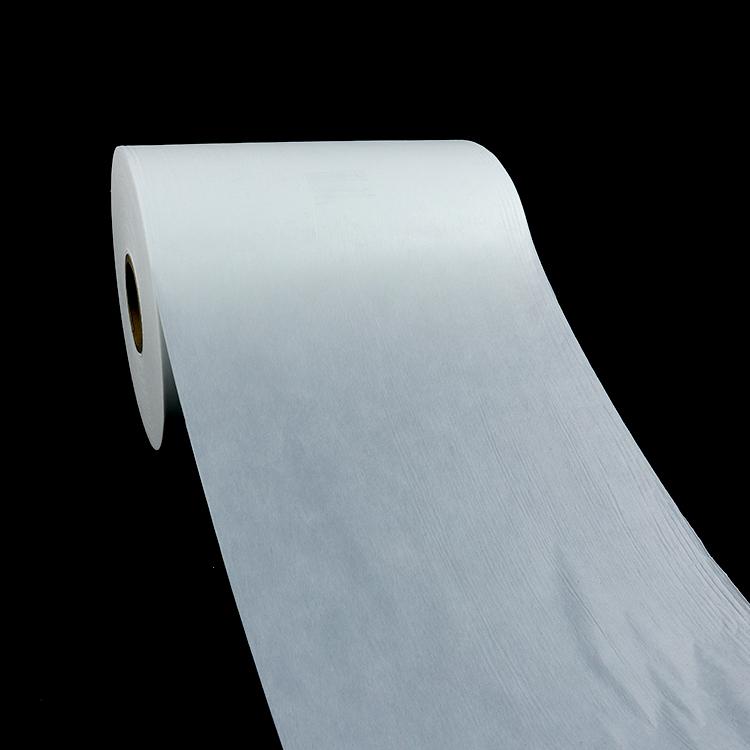

With the increase of the application fields of the membrane, the demand for the membrane is increasing, and the performance requirements of the membrane are getting higher and higher. Therefore, Breathable lamination nonwoven backsheet is more and more recognized by people for its unique advantages. Before the composite film is wound, the composite film will be cut into the size required by the customer, and the width of the composite film required by each customer is inconsistent. Therefore, sometimes the composite film with a large width needs to be cut into multiple rolls with a smaller width. In either case, it is often necessary to adjust the position of the cutter. At present, the distance adjustment of the cutter is mainly realized by manually moving the cutter. It is very inconvenient to operate.

In order to solve the above problems, Jiang Fei proposed a cutting device for Breathable lamination nonwoven backsheet. Its technical solution is: a cutting device for Breathable lamination nonwoven backsheet, including a casing, the inner wall of the casing is sequentially installed with a winding shaft, a cutting shaft and a transmission shaft, and the cutting shaft is located between the winding shaft and the transmission shaft. In the middle of the transmission shaft, a motor is fixedly installed on one side of the housing, and the output shaft of the motor runs through one side of the housing and is fixedly connected to one end of the winding shaft. The inner bottom surface of the housing is fixedly equipped with a slide rail, so A sliding body is placed above the sliding rail, a groove hole is provided at the bottom of the sliding body, and the sliding rail is located in the groove hole, a blade is arranged on one side of the sliding body, and the blade is positioned between the cutting shaft and the Between the transmission shafts, a blade fixing device is provided at the bottom of the blade, and a plurality of fixing holes are provided on one side of the slide rail, and a limiting device is provided between the groove hole and the slide rail, and the sliding body There is a cavity inside the bottom end of the other side, and a gasket is fixedly installed on the outer surface of the bottom end of the slider, and the gasket covers one side of the cavity, and a spring is arranged between the gasket and the cavity. , the middle of the spring passes through a lifting rod, one end of the lifting rod passes through one side of the sliding body and extends into a fixing hole thereof, the surface of the lifting rod is fixed with a limit block, and the limit block is arranged on In the front of the spring, the limit block is located in the cavity, the surface of the gasket is fixedly installed with an end cover, the other end of the lifting rod penetrates the gasket and the end cover and extends out, and the bottom surface of the end cover is set There is a screw, and one end of the screw passes through the gasket to connect with the sliding body, the surface of the lifting rod is provided with a through hole, one side of the end cover is threaded with a screw rod, and one end of the screw rod is inserted into the through hole, the A measuring device is arranged under the end cap.

Compared with the prior art, this technical solution has the following beneficial effects:

A. The output shaft of the motor drives the rewinding shaft to rotate quickly. The rewinding shaft drags the breathable composite film through the transmission shaft and the slitting shaft. The Breathable lamination nonwoven backsheet on the slitting shaft is cut by the approaching blade and then rewound by the rewinding shaft to achieve The cutting and winding of the Breathable lamination nonwoven backsheet are realized. The bolt can fix the blade on the sliding body, preventing the blade from slipping and realizing the installation and fixing of the sliding body to the blade. The sliding rail can assist the sliding of the sliding body. The chute and The slide block can make the sliding body move freely on the slide rail, and is used to adjust the position of the blade, thereby realizing the free movement of the blade. The installation of wheels can facilitate the movement of the whole device and facilitate people's use thereof.

B. The cavity realizes the placement of the spring, and the fixed limit block on the lifting rod realizes the compression of the spring, so that one end of the lifting rod extends into the fixing hole to abut against its surface, thereby realizing the clamping of the sliding body on the sliding rail , pull the lifting rod outward, tighten the screw, the screw rod is threadedly connected with the end cover, one end of the screw rod is inserted into the through hole, so that one end of the lifting rod is far away from the fixing hole, and the locking of the lifting rod is realized, so that the sliding body It can move freely on the slide rail. The gasket realizes the installation and disassembly of the spring. By setting the pointer and the scale line, the staff can accurately adjust the position of the blade. The screw realizes the end cover and gasket fixed on the sliding body. surface, preventing end caps and gaskets from falling off.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China