Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-09

At present, the non-woven fabric industry is in a period of vigorous development, and its importance in the field of medical and health care is becoming more and more significant. Especially the emergence of various viral influenzas has made non-woven fabrics make great contributions to medical and sanitary products. In nonwovens, anti-adhesive-meltblown composite materials account for a large proportion, among which SMS materials are more common and develop rapidly. With the complexity of diseases and the improvement of people's quality of life, high-quality SMMS composite nonwovens can better meet the development and needs of the times. This article briefly introduces the production process of SMMS legcuff non woven fabric.

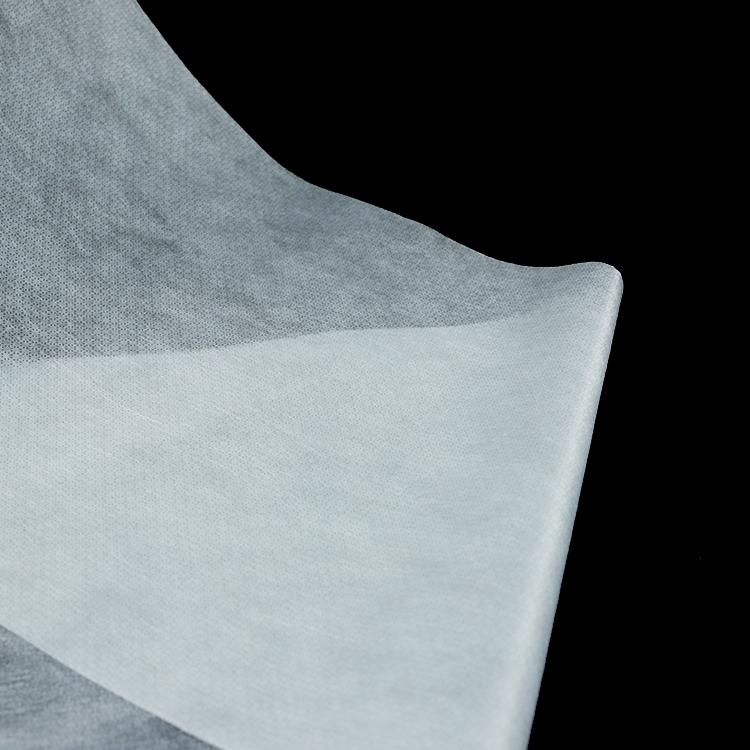

SMMS legcuff non woven fabric is made of polypropylene slices, which is composed of 4 layers of fabric (upper and lower layers of spunbond fabric, and middle layer of two layers of meltblown fabric) through hot-melt compounding. There are many similarities between the spunbond process and the meltblown process. Most of them use the one-step method, also known as the online composite method, which is completed by using the spunbond and meltblown equipment on the same production line, and finally through a one-time hot rolling process. The product SMMS non-woven fabric was obtained. This method is continuous production, and the process combines two different web forming technologies, which has the characteristics of short process, low cost, superior product performance and high production efficiency.

The production line of SMMS legcuff non woven fabric has two spunbond nozzles and two meltblown nozzles. The non-woven fabric produced has 4 layers, the upper and lower layers of spunbonded non-woven fabric have higher strength, and the middle two layers of melt-blown fabric use ultra-fine fibers. Raw material 1 is put into the spunbond screw through the feeding port, heated and melted, and passed through the metering pump, and the melt ejects a certain amount of primary fibers from the spinneret holes, and then is drawn by air flow to form a uniform fiber web on the web curtain. .

The raw material 2 passes through the melt-blown screw, and after being melted at high temperature, under the condition of high-speed airflow, it is extremely stretched to form ultra-fine filaments or ultra-fine short fibers, and then cools and strengthens the thick fibers, which are laid on the fiber web 1 to form fibers. net2. According to the process, use the same melt-blown and spun-bonded process, and finally compound on the web forming machine to obtain a fluffy fiber web 4. The fiber web 4 is finally formed into a web through a double-roll hot rolling mill, and then wound into a SMMS legcuff by a winder. non woven fabric.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China