Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-07

Unveiling the Secrets of PP Nonwoven in Diaper Production

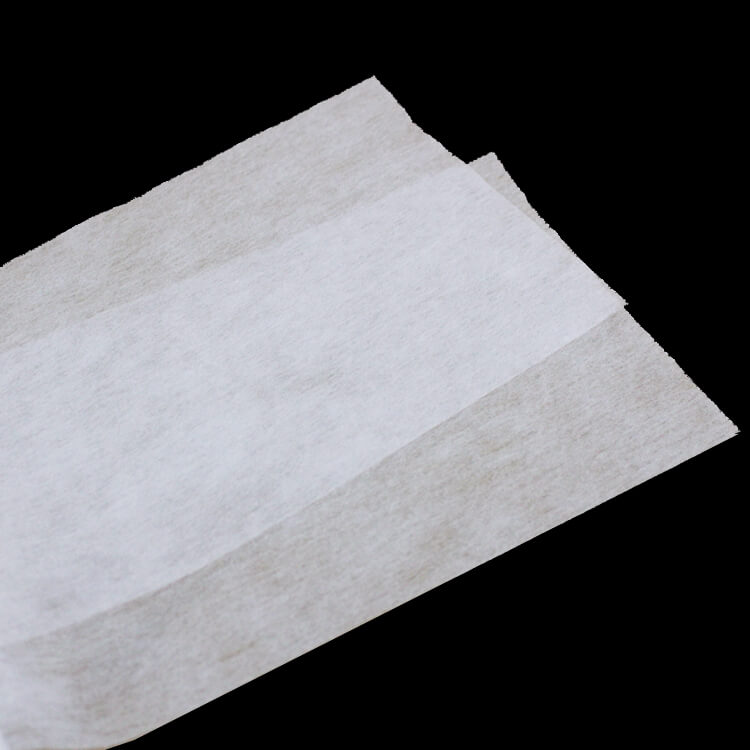

Diapers are an essential item for infants and toddlers, providing comfort and convenience for both children and parents. Behind the softness and absorbency lies a crucial component - PP nonwoven fabric. This article aims to unveil the secrets of PP nonwoven in diaper production, exploring its benefits, manufacturing process, and environmental impact. Understanding the role of PP nonwoven in diapers will shed light on how this material contributes to the overall performance and sustainability of these everyday essentials.

PP nonwoven fabric is the primary material used for the topsheet, backsheet, and acquisition layer in diapers. Its numerous advantages make it an ideal choice for diaper manufacturers. Firstly, PP nonwoven is highly breathable, allowing air circulation while preventing leakage. This helps in maintaining dryness and minimizing the risk of diaper rash. Secondly, it has excellent liquid absorption capacity, quickly capturing and distributing urine across the diaper surface. This ensures maximum comfort for the baby and reduces the chance of leakage. Additionally, PP nonwoven is soft and gentle on the skin, providing a cozy feel for the baby's delicate bottom.

The production of PP nonwoven involves several stages, each contributing to the fabric's unique properties. The process starts with polymerization, where propylene monomers are combined to form polypropylene pellets. These pellets are then melted and extruded through fine nozzles to create continuous filaments. The filaments are further cooled and stretched to improve their strength and durability. Next, the filaments are laid randomly or in a controlled manner to form a web, which is then bonded together using heat, pressure, or adhesive. The final step involves finishing treatments, such as calendaring or embossing, to enhance the fabric's surface characteristics.

While PP nonwoven fabric offers exceptional performance in diapers, it's essential to consider its environmental impact. PP is a thermoplastic polymer, meaning it can be recycled and reprocessed multiple times without significant loss in quality. This makes PP nonwoven a sustainable choice for diaper production. Furthermore, the manufacturing process of PP nonwoven consumes less energy and generates fewer greenhouse gas emissions compared to other materials like cotton. However, proper disposal and recycling systems are crucial to ensure the responsible use of PP nonwoven and minimize its impact on the environment.

In conclusion, PP nonwoven plays a vital role in diaper production, contributing to the comfort, absorbency, and overall performance of diapers. Its breathable nature, liquid absorption capacity, and softness make it an ideal choice for the topsheet, backsheet, and acquisition layer. Understanding the manufacturing process and considering its environmental impact allows us to appreciate the value of PP nonwoven in creating sustainable and efficient diaper products.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China