Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-31

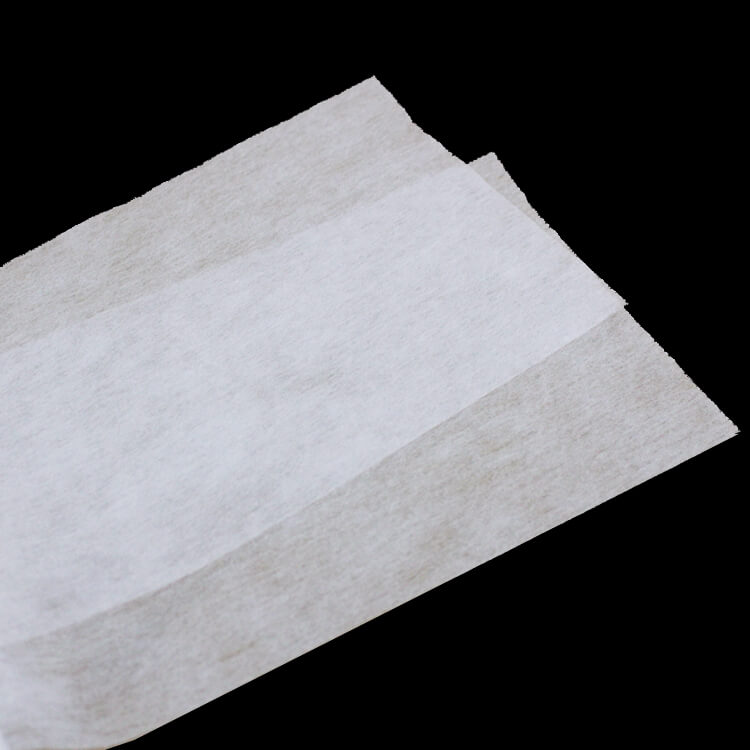

PP nonwoven fabric is a crucial material in the production of diapers. It provides excellent breathability, softness, and liquid absorption, making it the preferred choice for diaper manufacturers. However, to ensure the quality and efficiency of diaper production, it is essential to have a comprehensive understanding of PP nonwoven fabric. In this article, we will explore the essential knowledge of PP nonwoven fabric for diaper production.

PP nonwoven fabric is made from polypropylene fibers through a series of processes. Polypropylene, a thermoplastic polymer, is melted and extruded to form continuous filaments. These filaments are then laid down randomly or in a specific pattern to create a web-like structure. Through heat and pressure, the filaments fuse together, forming a cohesive fabric. The fabric can be further treated with additives to enhance specific properties, such as liquid repellency or antimicrobial capabilities.

PP nonwoven fabric possesses several key properties that make it ideal for diaper production. Firstly, it has excellent breathability, allowing air circulation while inhibiting the growth of bacteria and fungi. This helps to maintain a dry and comfortable environment for the baby. Secondly, PP nonwoven fabric has a high tensile strength, ensuring the durability and dimensional stability of the diaper. Moreover, it exhibits superior liquid absorption and retention capabilities, preventing leakage and providing maximum protection for the baby's skin.

To ensure the quality of PP nonwoven fabric used in diaper production, strict quality control measures are necessary. Various testing methods are employed to evaluate the fabric's performance and adherence to specific standards. These tests include tensile strength testing, liquid absorption capacity testing, breathability testing, and microbial resistance testing. Additionally, visual inspections are conducted to check for any defects or irregularities in the fabric.

In conclusion, understanding the essential knowledge of PP nonwoven fabric is crucial for diaper production. The composition, manufacturing process, properties, and quality control measures are all vital aspects that need to be considered. By selecting high-quality PP nonwoven fabric and ensuring its compliance with industry standards, diaper manufacturers can produce diapers that are comfortable, reliable, and safe for babies.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China