Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

Unlocking the Potential of Thermal Bond Nonwoven in Diaper Materials

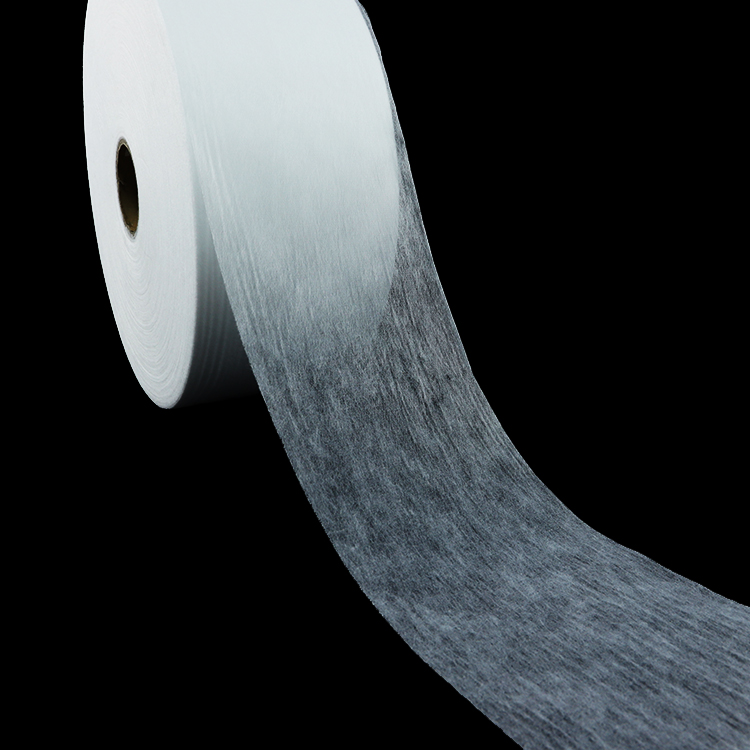

Diapers have come a long way since their invention, and with advancements in technology, manufacturers are constantly exploring new materials to improve their performance. One such material gaining attention is thermal bond nonwoven. Thermal bond nonwoven is a type of fabric made by thermally bonding fibers together, without the use of any binders or adhesives. This article aims to explore the potential of thermal bond nonwoven in diaper materials.

Thermal bond nonwoven has the capability to enhance the absorbency of diapers. The unique bonding process creates a fabric with a high density of interlocked fibers, which not only increases the overall surface area but also improves the capillary action. As a result, the diaper can effectively wick away moisture from the baby's skin, keeping it dry and comfortable for extended periods. Additionally, the enhanced absorbency prevents leakage, ensuring maximum protection.

Another significant advantage of using thermal bond nonwoven in diaper materials is the improved softness and comfort it provides. Traditional adhesives used in diaper construction can sometimes cause discomfort and irritations on sensitive baby skin. However, thermal bond nonwoven eliminates the need for adhesives, resulting in a smoother and softer surface. This material allows better air circulation, reducing the risk of diaper rash and promoting overall comfort for the baby.

In recent years, there has been an increasing focus on environmental sustainability in diaper manufacturing. Thermal bond nonwoven offers a solution in this regard. Unlike materials that require chemicals or solvents, thermal bond nonwoven does not contribute to chemical pollution during production. Additionally, this fabric is recyclable, further reducing its environmental impact. By incorporating thermal bond nonwoven into diaper materials, manufacturers can align themselves with the growing consumer demand for eco-friendly products.

In conclusion, thermal bond nonwoven has vast untapped potential in diaper materials. Its ability to enhance absorbency, provide improved softness and comfort, and contribute to environmental sustainability makes it a promising choice for manufacturers. As technology continues to advance, further research and development in this area can unlock even more benefits and lead to the creation of diapers that offer superior performance and reduced environmental footprint.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China