Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-19

Exploring PP Spunbond as a Key Component in Diaper Manufacturing

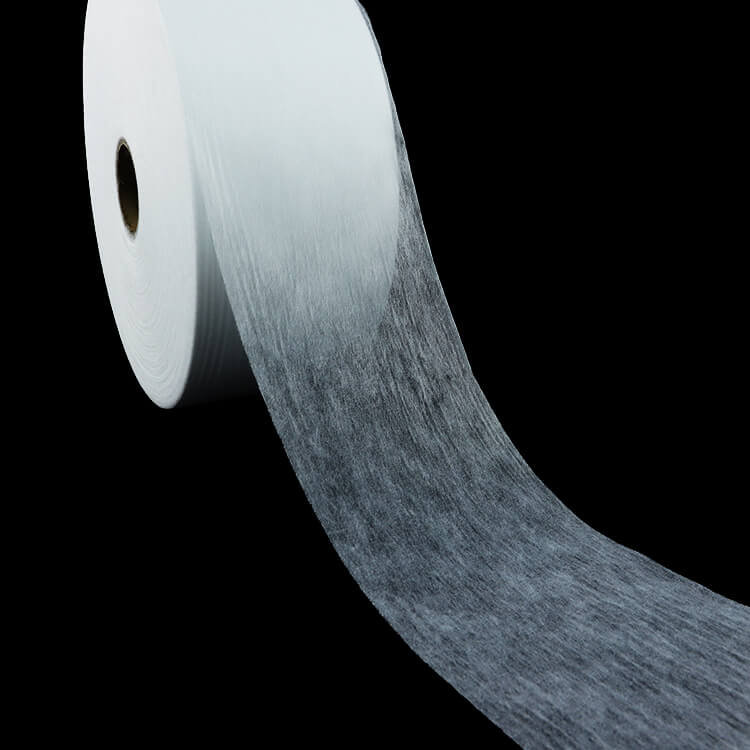

In the fast-paced world of diaper manufacturing, innovation and efficiency are essential. One key component that has revolutionized the industry is PP spunbond fabric. PP spunbond, short for polypropylene spunbond, is a nonwoven fabric made from thermoplastic polymer fibers. Its unique properties make it an ideal choice for diaper manufacturers seeking durable, breathable, and cost-effective materials. In this article, we will explore the various advantages of using PP spunbond fabric in diaper manufacturing.

Diapers are primarily designed to absorb and retain fluids to keep the baby's skin dry. PP spunbond fabric excels in this regard due to its inherent hydrophobic nature. The fabric repels water and prevents moisture from passing through, ensuring that the fluid is effectively contained within the diaper. Furthermore, the high surface tension of the fibers allows for quick absorption, distributing the liquid evenly across the fabric. This enhances the overall absorbency and fluid retention capacity of the diaper, keeping the baby comfortable and dry for extended periods.

Air circulation is crucial in maintaining healthy skin and preventing diaper rash. PP spunbond fabric offers excellent breathability, allowing air to pass through the diaper easily. The fabric's porous structure facilitates the dissipation of heat and moisture, reducing the chances of skin irritation. The soft texture of PP spunbond ensures a gentle feel against the baby's delicate skin, minimizing friction and the risk of discomfort. Diapers made with PP spunbond fabric provide optimal comfort, enabling the baby to move freely and enjoy unrestricted play.

Diaper manufacturers are always seeking cost-effective solutions that do not compromise on quality. PP spunbond fabric meets this requirement as it is relatively inexpensive to produce compared to traditional woven fabrics. The nonwoven nature of the fabric eliminates the need for additional sewing, saving both time and resources. Moreover, PP spunbond fabric is recyclable, making it an environmentally friendly choice. Its recyclability reduces waste and promotes sustainability in diaper manufacturing. By incorporating PP spunbond fabric, manufacturers can enhance their efficiency and reduce production costs while prioritizing environmental stewardship.

In conclusion, PP spunbond fabric is a key component in diaper manufacturing, offering numerous advantages such as enhanced absorbency, fluid retention, breathability, comfort, cost-effectiveness, and sustainability. Its unique properties make it an ideal choice for diaper manufacturers looking to provide high-quality products while maintaining efficiency and environmental responsibility. By embracing PP spunbond fabric, the industry can continue to innovate and meet the evolving needs of parents and caregivers worldwide.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China