Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

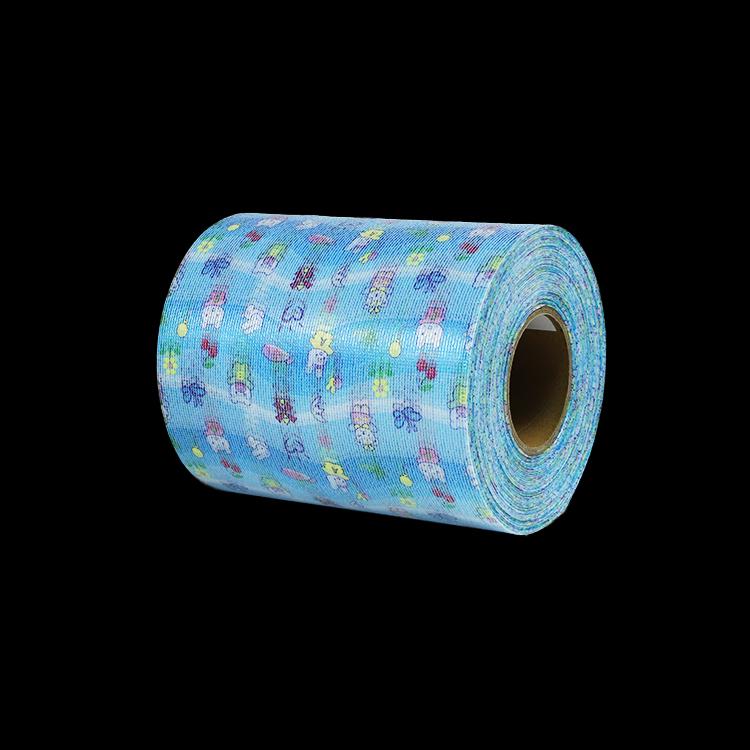

Application: Sanitary napkin

Minimum order quanity: 1000.00 kgs

Packing details: Carton packing

Position glue features:

Specially used in the feminine sanitary napkins, with high peel positioning performance for all back sheet whether applied for transfer slot or direct spray.

There is different brand position adhesive, such as Henkel, HB Fuller, Focus Glue and so on.

Shelf life:12 Months in dry and cool environment

Packing:18kgs/carton, 20kgs/carton

Loading quantity:12tons/20GP by pallets, 24tons/40HQ by pallets

Measures:

Skin contact:After contact with the hot melt: cool with water, seek medical attention.

Eye contact:After contact with the hot melt: cool with water, seek medical attention.

Inhalation: Move to fresh air, consult doctor if complaint persists.

Ingestion: If adverse health effects develop seek medical attention.

|

All the test are lot production averages |

|

|

||

|

Items |

Unit |

Requirement |

Result |

Method |

|

color |

|

light yellow solid |

light yellow solid |

Visual |

|

Softening point |

℃ |

82-94 |

91.7 |

Measurement |

|

Viscosity |

cp |

3000-5500 |

4455 |

|

Absorbent airlaid SAP paper features: Material: fiber+pulp+SAP Basic Weight: 90gsm-550gsm Diameter: less than 750mm Color:white Cost: theprice is depends on the composition...

Knitted frontal tape also called LOOP and magic frontal tape, has samefunction as pp frontal tape, to attached to the front of the diapers withadhesive, but this is a new generatio...

Silicone release paper features: Major ingredient: Paper+silicone Weight: 30-42gsm Width: 25mm-960mm Tension strength:≥45 (N/25mm) Release Force:N/25mm 0.08-0.25 Technology:...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China