Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Sanitary napkin,Baby diaper,Adult diaper

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

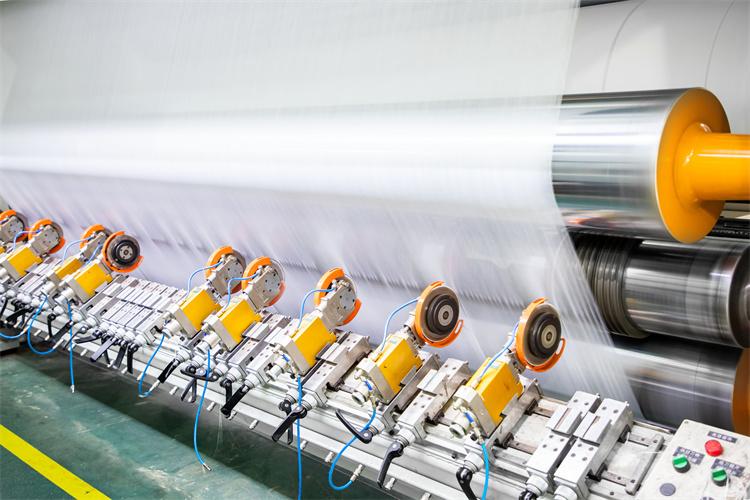

Spunbond Hydrophobic Non Woven Fabric Features:

Hydrophobic non wowen mainly used in leg cuff,elastic ear,elastic waistband,backsheet film of baby diapers. Also used in leg cuff of sanitary napkin.

Loading:5Tons/20GP;12Tons/40'HQ;

|

Product Name |

hydrophobic non woven |

|

Nonwoven Technics |

Spun-Bond |

|

Material |

100% Polypropylene |

|

Product Usage |

Baby diaper, sanitary napkin, adult diaper and undder pad |

|

Feature |

Anti-bacterial, Anti-static, Anti-UV, Fireproof, Waterproof, Hydropilic, Laminated(pp+pe), Printed, Preforation,etc. |

|

Gram Weight |

9gsm-100gsm |

|

Width |

Max 320cm at present, can be slitting as customer's requirement |

|

Tensionble test |

Elongation-MD(%):targe80-Max130 |

|

Printing |

Various design available or customized |

|

Color |

As per customer's requirement |

|

Packing |

Rolled with paper tube,packed with PE plastic bag |

Hydrophilichot air non woven fabric is a kind of hot air bonding (hot rolling,hot air) non woven fab ric. Hot air non woven is to usethe hot air on the drying equipment to penetr...

1.SMMS non woven fabrics (Spunbond + Meltblown + Meltblown + Spunbond Nonwovens), basic weight range: 10-100 gsm; width: 90mm-3200mm; it belongs to composite non woven fabrics, whi...

Thermal bond non woven fabric is generated by bicomponent fiber or PP with PET fiber. They have higher elongation in the CD and lower elongation in the MD. Composition: ES-fiber ...

Hydrophobic SMMS non Woven fabric is the abbreviation of “Spunbond + Meltblown +Meltblown+ Spunbond Non woven”, that is a combined nonwoven fabric which two layers spunbond have ...

The perforated film is mainly due to its own function. It is breathable and water permeable like gauze, but it does not stick to the packaging like gauze. Most of the perforated fi...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China