Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Baby diaper, Adult diaper

Minimum order quanity: 4 rolls

Packing details: Carton packing

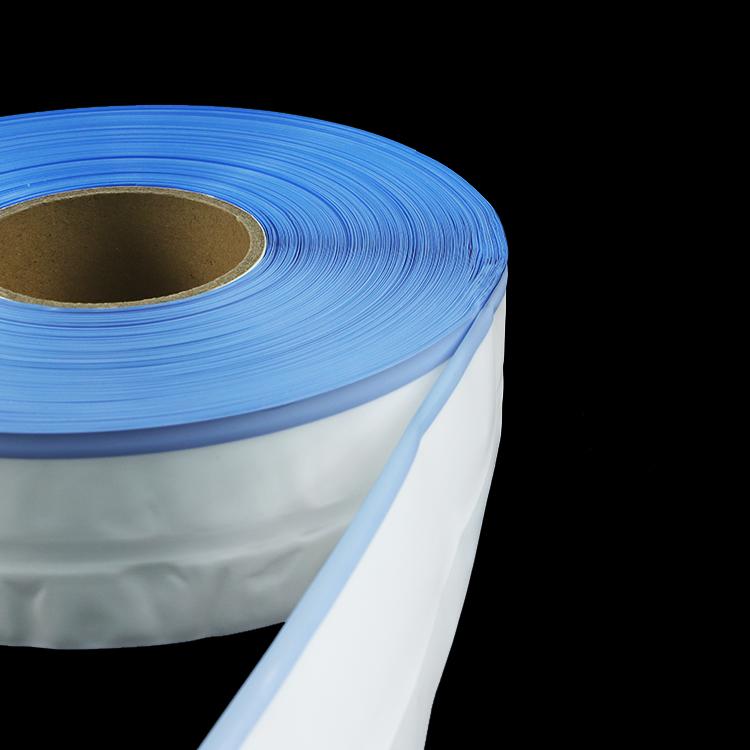

Frontal tape Product details:

Weight:39- 45g/m²

Width:200mm or as required

Roll diameter:as required

Length: 700m/roll

Inner core diameter: 76mm

Color:Printed or white

Application: baby diapers, adult diapers

Feature

(1) Soft and close to skin.

(2) Excellent hook with good holding power.

(3) Use combine with fastening frontal film and non-woven frontal film.

(4) Can be used repeatedly, prevent from besmirch and dust.

|

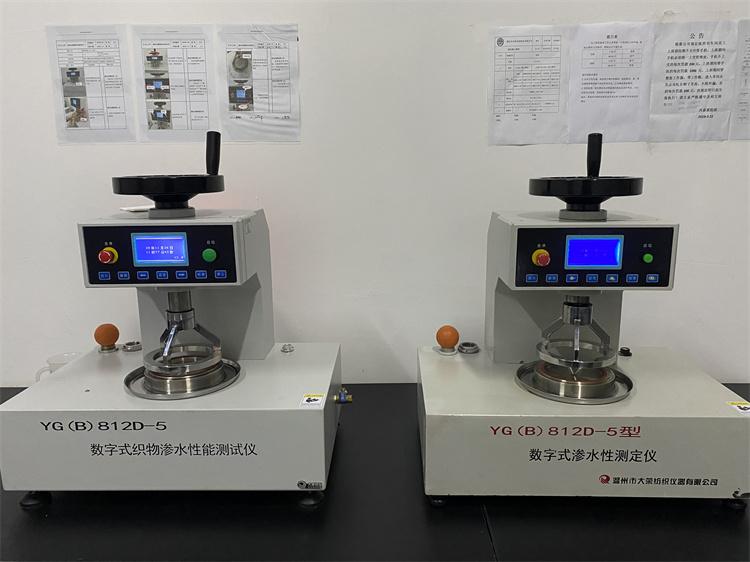

Items |

Unit |

Result 1 |

Result 2 |

|

Basic weight |

gsm |

44.5 |

45.2 |

|

Core Inner Diameter |

mm |

76 |

76 |

|

Width |

mm |

200 |

200 |

|

0º tension |

N/15mm*25mm |

30 |

31 |

Adhesive side tape features: (1) Excellent imported hook with good holdingpower. (2) Can be used repeatedly, prevent from besmirch and dust. (3) Soft and close to skin. (4) Use co...

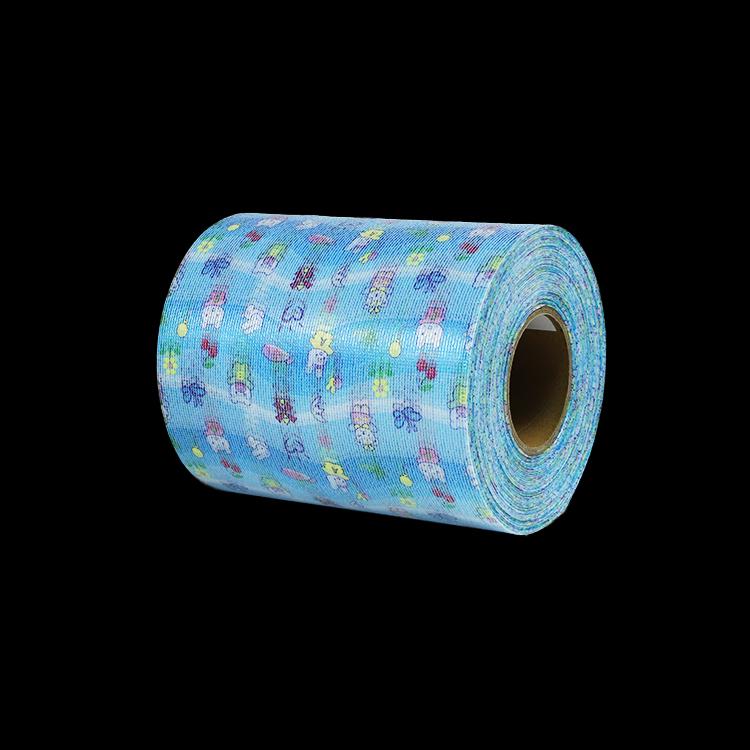

Wetness indicator glue features: 1) Our productsare nontoxic,pollution-free,clean,and tensile 2) Soft andconfortable 3) Printing:Printed and non-printed 4) We canprovide the co...

Knitted frontal tape also called LOOP and magic frontal tape, has samefunction as pp frontal tape, to attached to the front of the diapers withadhesive, but this is a new generatio...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China