Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Sanitary napkin,Baby diaper,Adult diaper

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

Untreated fluff pulp features:

Untreated fluff pulp is used for baby diaper,sanitary pad and adult diaper.

Color:White

Loading quantity:25tons/40HQ

Untreated fluff pulp is a common ingredient in the production of baby diapers. Fluff pulp is a type of wood pulp that is used as a absorbent material in many personal care products, including baby diapers. It is typically produced by the pulping of wood chips, which are then refined and processed to create a soft, absorbent material that is used in the production of baby diapers. In the production of baby diapers, untreated fluff pulp is typically combined with other materials, such as superabsorbent polymers, to create a product that is both absorbent and durable.

|

Items |

Unit |

Requirement |

Result |

Method |

|

Color |

|

White |

white |

Visual |

|

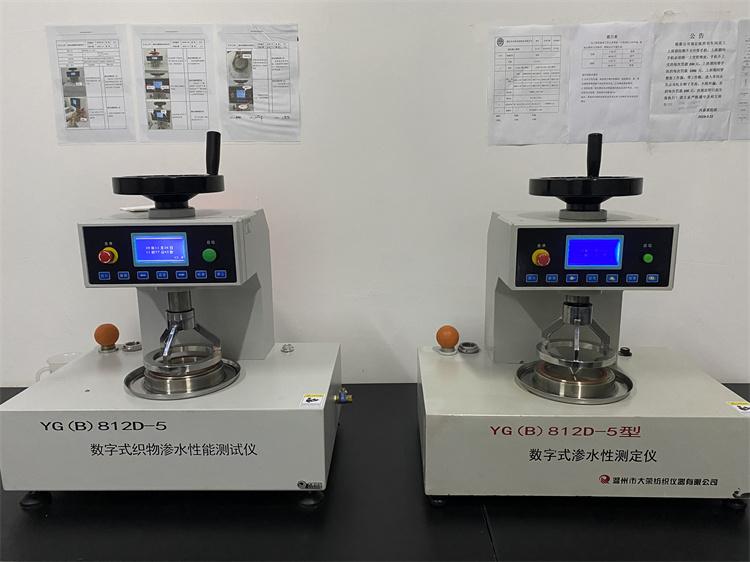

Moisture |

% |

10 |

10 |

Measurement |

|

Brightness |

%ISO |

86 |

86 |

Measurement |

|

Mullen |

kPA |

1035 |

1035 |

Measurement |

|

Basis weight |

g/m2 |

750 |

750 |

Measurement |

|

Density |

kg/m3 |

625 |

625 |

Measurement |

|

Others |

Wrinkles/ corrugation |

None |

Visual |

|

|

Splices |

None |

|||

|

Roll edge appearance |

Neat, Clean, No Obvious Defects |

|||

|

Contamination |

No Obvious Contamination; Free From Foreign Matter |

|||

|

Holes/Thin spots/Formation |

No Obvious Holes / Thin Spots / With Good Formation |

|||

Email: info@juhuascm.com

Email: info@juhuascm.com

MP/WhatsApp: +86-13599104026

MP/WhatsApp: +86-13599104026

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China